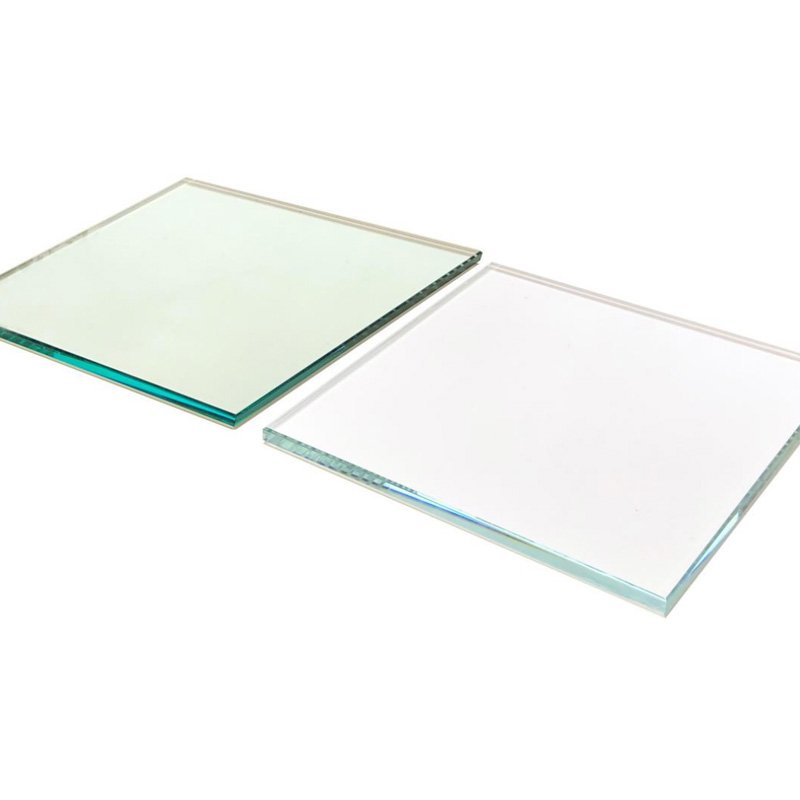

Recently, many people in the selection of bathroom glass will have questions: why standard glass looks visually more green, and low iron glass looks more white. As the leading glass manufacturer and supplier, MIGO Glass offers custom low iron glass and standard glass at best factory price in bulk order. This article, we will delve into the comparison of low iron glass vs standard glass. This will help you find which kind of glass is the best choice for the bathroom.

1. What Does Low iron Glass Mean?

Low iron glass, also known as optically clear glass, is a specialized type of glass with extremely low iron content. Compared to traditional glass, low-iron glass has significantly reduced levels of iron, resulting in the removal of the blueish tint that is commonly associated with thicker glass.

MIGO Glass is a manufacturer that produces low-iron glass, offering a variety of options suitable for interior applications, decorative glass, exterior façades, vision glazing, and more.

The distinguishing feature of low-iron glass is its exceptional clarity and minimal green tint. The reduced iron content in this glass type enhances its transparency and color accuracy. When utilized in bathrooms, low-iron glass provides a clearer and more transparent visual effect, contributing to a brighter and modern ambiance. Unlike regular glass, low-iron glass is completely transparent due to the decreased iron content in its molten glass composition, allowing for an unobstructed view.

Aside from its clear view, low-iron glass also offers advantages in terms of edge treatment, which is less environmentally impactful compared to standard transparent glass. This means that the manufacturing process of low-iron glass is designed to minimize its environmental footprint.

2. What Does Standard Glass Mean?

Standard glass is a type of glass that undergoes an annealing process, resulting in rapid cooling. This process is responsible for its unique properties and popularity in various applications. One notable feature of standard glass is its reworkability, allowing for modifications without the risk of breakage or shattering. It can be easily cut, reshaped, edges polished, and holes drilled.

When standard glass breaks, it forms large, irregular-shaped shards, which can be advantageous in terms of safety. This characteristic makes it suitable for diverse uses such as picture frames, tabletops, desktop glass, shelves, storm windows, and cabinet glass.

In its typical form, standard glass appears as clear glass with a slight green tint on the surface. This green hue is a result of the presence of iron content within the glass. When clear glass is used in bathroom settings, it may slightly impact the clarity of light transmission. While not completely transparent, careful observation may reveal a subtle green tint or green edges. This tint becomes more noticeable when viewed from specific angles and increases in intensity with greater glass thickness.

The green tint in standard glass is caused by naturally occurring iron oxides present in elements like sand or from the barrels and containers used during the glass melting process. These iron oxides contribute to the unique coloration of the glass, distinguishing it from completely transparent variants.

Standard glass offers versatility, reworkability, and a characteristic green tint that can add aesthetic appeal to various applications while maintaining its structural integrity.

3. What Is The Differenceof Low Iron Glass vs Standard Glass?

3.1 Different Strength

Low iron glass can be tempered, making it significantly stronger than standard glass. Standard glass is comparatively more fragile. Low iron glass is approximately four times stronger, thanks to the slower annealing process during tempering, which enhances its strength. It is often utilized for safety reasons due to its increased durability. When tempered low iron glassbreaks, it breaks into small pieces, harmless for the most part.

3.2 Different Processing Method

Low iron glass and standard glass undergo different processing methods, resulting in varying characteristics. Low iron glass is processed at a slower pace, which contributes to its superior strength and makes it suitable for safety applications.

Standard glass, on the other hand, is subjected to a rapid annealing process. This process involves quick cooling of the glass. Standard glass is favored for its reworkability, allowing for customizations like cutting, reshaping, polishing edges, and drilling holes without the risk of breakage or shattering. However, the downside of the fast annealing process is that standard glass is more fragile compared to low iron glass. When standard glass breaks, it forms large, irregular-shaped shards.

Low iron glass benefits from a slower processing method, resulting in enhanced strength and its preferred use for safety purposes. Standard glass, while reworkable, is more fragile due to the faster annealing process and is prone to breaking into larger shards.

3.3 Different Visual effect

Low iron glass has higher transparency and permeability, the installation on the bathroom door can allow light to flow more smoothly through, and the space appears more bright, spacious and transparent. The color of the Low iron glass is pure and does not produce green or blue tones, presenting a clearer and natural visual effect, making the entire bathroom more refreshing and comfortable.

The transparency and permeability of clear glass is low, which is easy to produce reflection and refraction, affecting the visual effect. In addition, the color of ordinary clear glass is green or blue, which is not as pure and clear as low iron glass, which may make the bathroom appear dull and depressing.

3.4 Different Environmental protection property

Due to the low iron content of low iron glass, the production process reduces the pollution to the environment, in line with the modern environmental protection concept. The low iron glass surface is smooth, easy to clean, not easy to accumulate dust, and maintain the cleanliness and transparency of the bathroom door.

The high iron content in the production process of clear glass may produce a certain degree of pollution, which is not as environmentally friendly as low iron glass. In addition, the surface of ordinary clear glass is relatively rough, easy to accumulate ash, and requires frequent cleaning and maintenance.

3.5 Different Price

Due to the high production process and material cost of low iron glass, the price is relatively expensive. But considering its superior visual effect and environmental protection, choosing low iron glass as a bathroom door is also a good choice.

The production process and material cost of clear glass are low, so the price is relatively cheap. If the budget is limited or the visual requirements are not high, choosing clear glass as a bathroom door is also an affordable option.

4. How To Choose Right Glass Between Low Iron Glass vs Standard Glass

Low iron glass and standard glass are different in many aspects, it’s important to consider various factors to ensure you choose the right option for your specific needs.

4.1 Strength and Safety

If strength and safety are paramount, tempered glass is the recommended choice. Both low iron glass and standard glass can be tempered, providing enhanced strength and the ability to shatter into small, safer fragments when broken. Tempered glass is ideal for applications where impact resistance is crucial, such as windows, doors, or glass panels in high-traffic areas.

4.2 Transparency

Low iron glass excels in transparency and color accuracy due to its reduced iron content. If your objective is to achieve high clarity and minimal tint, low iron glass is the preferable option. It offers a clear, colorless appearance, making it suitable for applications where visual purity is important, such as display cases or architectural glass elements.

4.3 Aesthetics

Low iron glass is specifically designed to minimize the greenish tint present in standard glass. If you prioritize a neutral, transparent look with minimal color distortion, low iron glass is the better choice. It allows for the true colors of objects or views to be displayed without the interference of a noticeable tint.

4.4 Customization

Standard glass is known for its reworkability, making it easier to cut, reshape, and drill without the risk of breakage. If your project requires extensive customization or specific dimensions, standard glass may be the more suitable option. It offers greater flexibility in terms of modifications and adjustments.

As the glass manufacturer and deep processor, MIGO Glass has its own factory to offer glass customization for your needs.

4.5 Price

Low iron glass typically comes at a higher price point compared to standard glass due to its enhanced clarity and specialized manufacturing process. Consider your budget and weigh it against the desired attributes. If the superior transparency and aesthetics of low iron glass align with your project requirements and budget, it may be worth the investment.

The choice between low iron glass and standard glass depends on your specific needs and priorities. Evaluate the factors of strength, transparency, aesthetics, customization, and price to determine which type of glass best suits your project or application.

5. Conclusion

The difference between low iron glass and stardard clear glass as a bathroom door is mainly reflected in the material characteristics, visual effects, environmental protection and price. Low iron glass has higher transparency and permeability, showing a more clear and natural visual effect, environmental protection is better, but the price is relatively expensive; clear is cheap, but the visual effect and environmental protection are poor. Therefore, when choosing the bathroom door material, you can choose according to your personal needs and budget to achieve the best decoration effect.

MIGO Glass has a professional team to help you understand the difference between clear glass and low iron glass, and you can give related small samples for free for observation.

If you want to know more about glass, please contact us