Shower Glass Hole Drilling

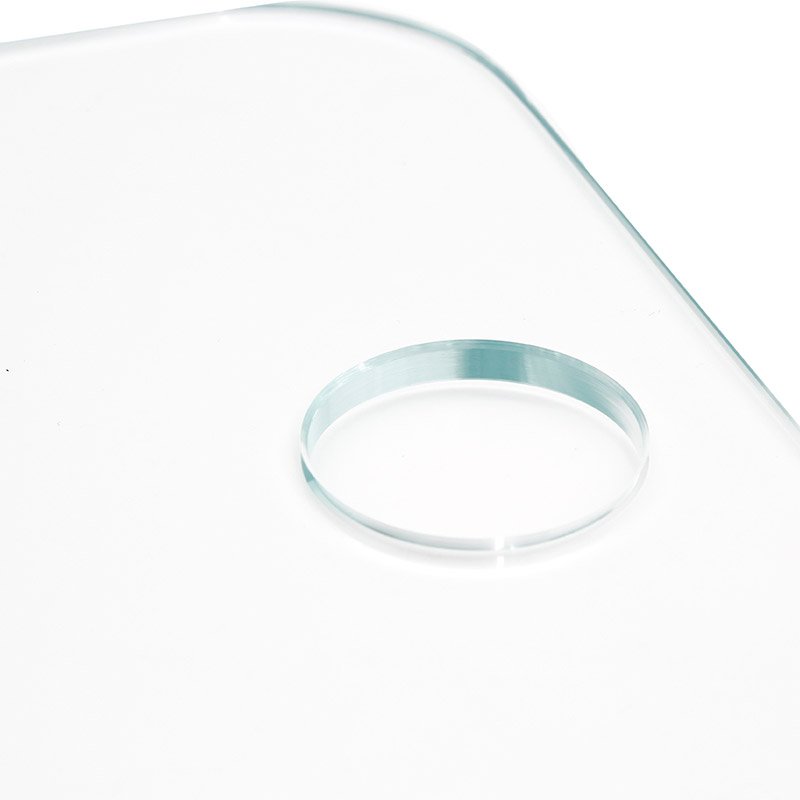

Shower glass hole drilling is an important fabrication process for shower glass deep processing. It refers to the application of special equipment, supporting tools and auxiliary materials to drill holes in glass with optimum processes to realize glass installation and fixation in bathroom. MIGO Glass provides cutom glass hole drilling service for your demands at great price.

Table of Contents

1. Why Do Drill Holes on Shower Glass?

During the bathroom installation process, when the bathroom glass is fixed or connected to shower glass door hinges, shower glass clamps, shower glass door handles or glass shower door knobs, it is generally necessary to drill holes in glass. The most asked questions are how to drill holes in glass, how to cut a hole in glass or how to make a hole in glass without tools? The right answer is using hole drilling machine to drill holes in glass. MIGO Glass has its own largest glass processing factory to drill holes in different glass sizes. Our advance CNC glass drilling machine can drill holes in glass with diameter up to 200mm,2~20mm thickness, the maximum size of processed glass is 2600X1800mm.

2. Can You Drill a Hole in Tempered Glass?

In order to improve the strength and safety of glass shower, the finished shower glass is generally tempered glass. The most asked question is can you drill a hole in tempered glass? Perhaps you can perform glass hole drilling in tempered glass. But the glass is tempered before cutting. If it is damaged and processed, the tempered glass will be broken into small fragments without sharp angles. Therefore, in the glass drilling process, the glass is generally processed to the required shape before tempering, and then tempered.

3. Preparation Before Shower Glass Hole Drilling

3.1 Shower Glass Hole Drilling Machines

3.1.1 Power Drill

When installing and constructing simple holes on the bathroom site, generally choose a cordless hand drill and glass drill bit that fit the hole diameter. This glass drilling method has low processing accuracy and has the risk of breaking the glass.

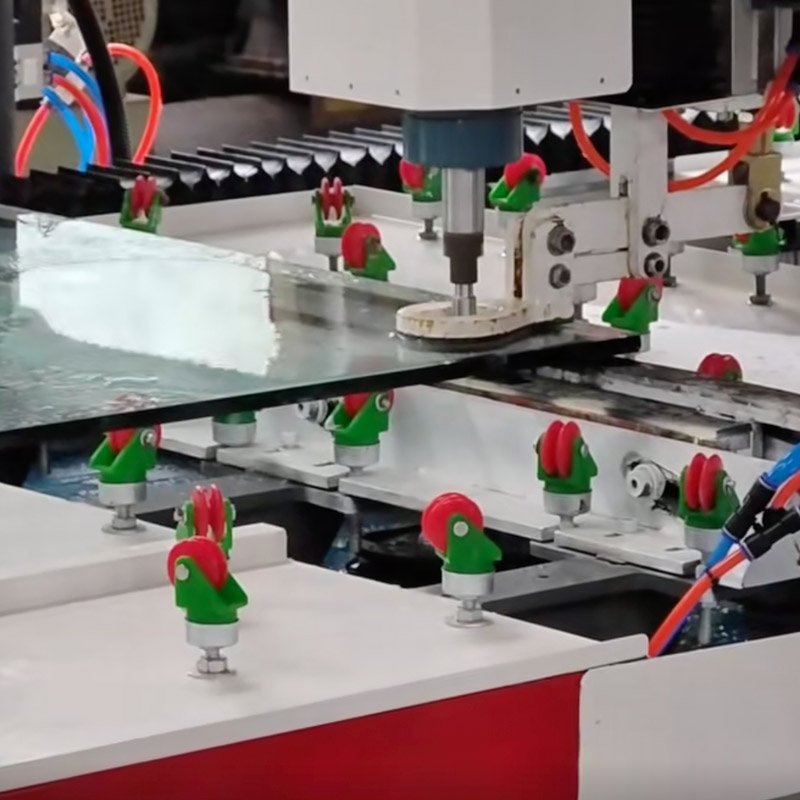

3.1.2 CNC Glass Hole Drilling Machine

CNC glass hole drilling machines can realize automatic glass hole drilling. It can control the drilling position, size and depth to ensure the hole drilling accuracy and consistency. The CNC glass hole drilling machine can process batch glass holes drilling with large sizes and high precision.

3.2 Glass Hole Drilling Tools

Hole drilling tools generally include drills and reamers

3.3 Coolants and Cleaning Fluids

Clean coolants can avaid damage to the glass surface and ensure the quality of glass processing.

4. How to Drill Holes in Glass?

Drilling holes in glass or drilling holes into glass is a technical and artistic work. MIGO Glass has many types of glass hole drilling machines such as hand glass drilling lathe, china glass holes drilling machine and CNC glass hole drilling machine for glass hole drilling process.

The CNC glass hole drilling machine uses computer control to precisely perform glass hole drilling. It can realize automatic and precise multi-position hole drilling by inputting CNC code and placing the glass as required.

To ensure quality and efficiency during processing, please follow the operating instructions below when drilling hole in glass.

4.1 Safe Operation

Before drilling, a protective film or tape needs to be applied to the glass surface to prevent scratches or damage. Make sure to wear appropriate personal protective equipment, such as goggles and gloves, to protect yourself from possible injury.

4.2 Drilling speed and pressure

It is necessary to coordinate the drilling pressure, feed speed and spindle rotation speed. Excessive speed or pressure may cause the glass to break or be damaged. The general spindle rotation speed is about 5000-15,000 rpm, the feed speed is about 0.1~0.5mm/s. The drilling pressure is relative to the feed speed, drill and glass materials.

4.3 Cooling and lubrication

During the glass holes drilling process, clean coolant is used for cooling and lubrication to reduce heat and friction and ensure the integrity of the glass.

4.4 Inspection & Precise measurement

Before glass hole drilling, be sure to take inspection, precise measurements and markings to ensure the accuracy of the drilling location and size.

MIGO Glass has 19+ years of custom shower glass processing experience with craftsmanship for your demands. If you have any questions or inquiries, welcome to contact us.