Shower Glass Cut Out

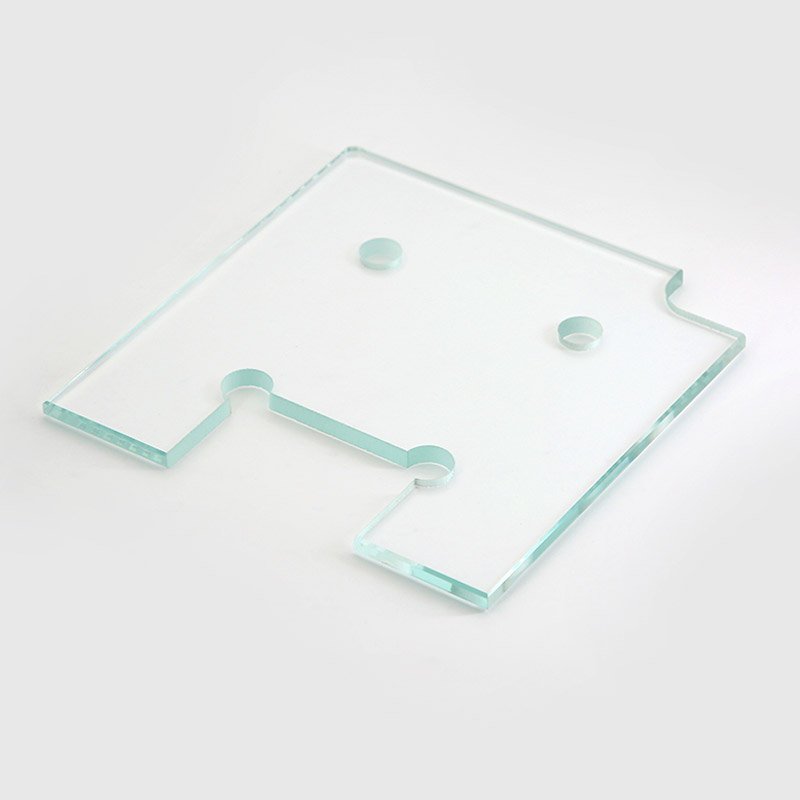

Shower glass cut out refers to removing a portion of material off shower glass to form grooves, notches or edges. The glass cut to size makes bathroom accessories install on glass convenient. And it is easy to insert metal brackets or adapt to specific design needs or installation requirements.

MIGO Glass is the leading shower glass manufacturer and supplier, our custom shower glass products include standard clear shower glass, tinted shower glass, frosted shower glass, patterned shower glass, low iron shower glass, and more. MIGO Glass provides custom glass cut out to size for your demands at competitive factory price.

Table of Contents

1. Why Do Cut Out on Shower Glass?

When working on any bathroom project, it is highly unlikely to find pre-cut shower glass that perfectly matches your design. Thus, you need to cut glass to size to meet your specifications. Cutting glass shower ensures a proper fit and achieves your design for the shower enclosure or glass shower doors. So, you will need shower glass cut to size with grooves, notches or edges to meet bathroom specifications.

2. How to Cut Shower Glass?

Shower glass cut out is an important glass fabrication process and service for show glass door or glass shower enclosure installation. Can you cut shower glass? You will need the proper tools to cut your glass. Custom-cut shower glass typically requires glass processing equipment such as CNC glass milling machine or CNC glass machining center.

Hand-cutting tools such as power drills or glass knives are suitable for on-site installation or workshops.

2.1 Hand Glass Cut to Size

Glass knife refers to a hand tool for glass cut to size. Diamond or alloy material is harder than glass, glass knife often take diamond or alloy material as the cutting part. It is suitable for cutting flat glass with a thickness of 1-8 mm. To properly complete the glass cutting, you should have workbench, straightedge guide, cutting oil, window cleaners, and safety goggles, etc.

To begin cutting, take your straight edge and use it as a guide for precision. To achieve a smooth cut, apply cutting oil to minimize friction. For larger pieces, secure the straightedge in place with duct tape to prevent any slippage. During the cutting process, exert firm pressure on the cutter to ensure optimal results.

When you finish glass cut to size, be careful to separate the cut glass. The hand glass cut out method is suitable for simple shape suck as straight edge or rounded holes. This method is difficult to accomplish complex shape of glass cutting as shown in the right picture.

2.2 Glass Cut to Size Using CNC Machine

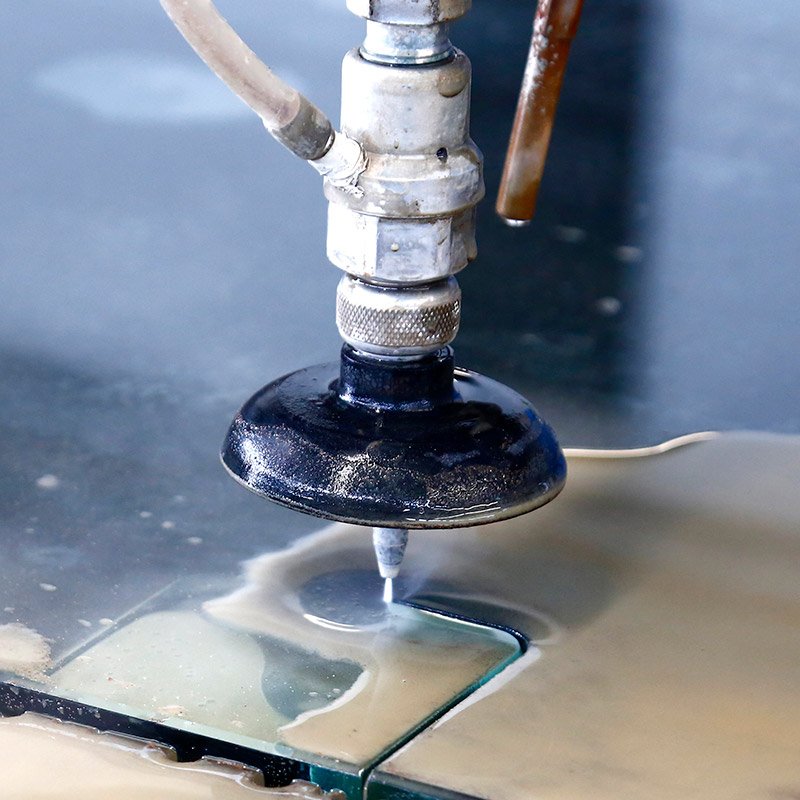

MIGO Glass processing factory adopts automatic CNC glass Cutting and Milling Machines for bulk glass processing effectively and efficiently. It can carry out custom shower glass cutting with desired opening shape, size and location for your demand.

CNC glass cutting and milling machine can perform glass cutouts for complex glass shapes such as grooves, notches or edges. It combines computer numerical control technology with high speed rotating cutters and milling tools to achieve accurate and efficient glass processing. It can process various types of glass, including flat glass, laminated glass, and even curved glass, depending on the machine’s capabilities.

It provides high precision and repeatability, ensuring consistent and accurate cut out or milling operations. It can handle complex shapes, intricate patterns, and beveling with ease, allowing for intricate glass designs. Additionally, It often has such features as automatic glass thickness detection, edge detection, and optimization algorithms to maximize material utilization. Some of them may also have additional functionalities like drilling holes, engraving, or edge polishing, expanding their versatility in glass fabrication.

2.3 Glass Cut Out Process for CNC Machine

2.2.1 Set Up

Create a CAD of the desired shower glass cut out as the input for the CNC glass machine. Prepare the CNC Glass Machine by securely fixing the glass sheet onto the machine’s working table. Ensure proper alignment and calibration of the machine based on the design specifications.

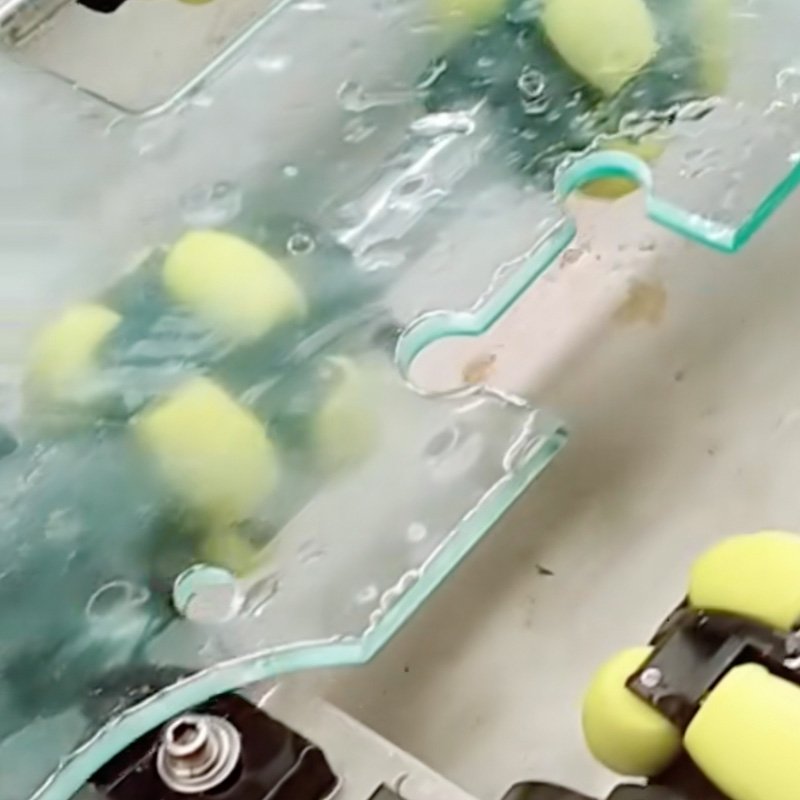

2.2.2 Cutting and Milling

Start the CNC machine, input the NC code, and choose appropriate cutting and milling tools based on the required cut-out design. It will automatically execute the programmed instructions. The CNC machine will precisely cut and mill the glass according to the design, following the designated paths and contours. If necessary, perform additional finishing and polishing processes to refine the edges or surfaces of the cut-out section.

2.3.3 Inspection

Inspect the glass cut-out section to ensure accuracy and quality.