As a glass manufacturer and supplier, MIGO Shower Glass understands the importance of packaging for shower glass during transportation. The fragility of shower glass necessitates proper packaging and protection to ensure its safe arrival at its destination. How To Pack Shower Glass For Safe Transportation? Here’s a detailed discussion on this topic.

1. Types of Shower Glass Packaging

Shower glass packaging comes in various types, each designed to offer protection, convenience, and aesthetic appeal. Here are some common types:

1.1 Carton Box

Carton boxes are widely used as the most basic type of packaging for shower glass. They provide a practical and cost-effective solution for protecting the glass during transportation and storage. While they may not offer the same level of protection as specialized packaging options, such as wooden crates or foam inserts, cardboard boxes still provide reasonable safeguarding against scratches and minor impacts.

The versatility of cardboard boxes allows for customization based on the specific requirements of the shower glass. They are available in various sizes to accommodate single or multiple pieces of glass, ensuring a snug fit and minimizing movement within the box during transit. Additionally, the boxes can be tailored to include branding elements such as the company logo, product information, and handling instructions. This makes them ideal for retail display, as they not only protect the glass but also serve as a means of promoting the brand and showcasing the product’s features.

Cardboard boxes offer several advantages beyond their protective function. They are lightweight, easy to handle, and cost-effective to produce, making them a practical choice for packaging and shipping large quantities of shower glass. The recyclable nature of cardboard also aligns with eco-friendly practices, appealing to environmentally conscious consumers and businesses.

To enhance the protective capabilities of cardboard boxes, additional measures can be taken, such as incorporating foam inserts or corner protectors to provide extra cushioning against impacts. These additions help to further minimize the risk of damage during transportation or handling.

It is important to note that while cardboard boxes offer a convenient packaging solution, they may not be suitable for long-distance or extremely fragile shipments. In such cases, specialized packaging options may be necessary to ensure the highest level of protection for the shower glass.

Overall, cardboard boxes provide a practical and customizable packaging solution for shower glass. Their affordability, versatility, and branding potential make them an attractive choice for both manufacturers and retailers. By combining adequate protection with effective marketing, cardboard boxes contribute to a positive customer experience and help to ensure the safe arrival of shower glass products to their intended destinations.

1.2 Wooden Crates

When it comes to packaging heavy or fragile shower glass panels, wooden crates are a preferred choice due to their exceptional strength and durability. These crates offer superior protection against impacts, making them ideal for long-distance shipping or transportation in challenging environments.

Wooden crates are designed to withstand the rigors of handling and provide a robust barrier against external forces. The sturdy construction of the crates ensures that the shower glass panels remain secure and well-protected throughout the entire journey. This is particularly crucial for delicate or oversized glass panels that require extra care during transportation.

One of the advantages of wooden crates is their customizability. They can be tailored to fit the specific dimensions of the shower glass panels, ensuring a snug and secure fit. The interior of the crate can be lined with foam inserts or padding, which adds an additional layer of protection against potential impacts or vibrations during transit. This customization minimizes movement within the crate, reducing the risk of damage to the glass panels.

Wooden crates are also known for their reusability and sustainability. They can be disassembled and reconstructed, allowing for repeated use in multiple shipments. Moreover, wooden crates are often made from responsibly sourced materials, making them an environmentally friendly packaging option.

In addition to their protective qualities, wooden crates provide security, as they can be securely fastened and sealed. This helps prevent unauthorized access and reduces the likelihood of tampering or theft during transportation.

However, it is important to note that wooden crates tend to be heavier and bulkier compared to other packaging options. This may result in higher shipping costs and require specialized handling equipment. Additionally, the use of wooden crates may necessitate compliance with specific international regulations regarding wood treatments and certifications.

Overall, wooden crates offer a reliable solution for packaging heavy or fragile shower glass panels. They provide excellent protection against impacts, customization to fit panel dimensions, and the option to include additional padding for enhanced safety. With their robustness and reusability, wooden crates ensure that the shower glass panels arrive at their destination in optimal condition, ready for installation or display.

1.3 Customized Packaging

Customized packaging solutions for shower glass provide manufacturers with the opportunity to create a unique and tailored packaging experience. These solutions go beyond standard packaging options and allow for the integration of design elements, branding, and enhanced protective features.

One aspect of customized packaging is the design of custom boxes specifically crafted to accommodate the dimensions and shape of the shower glass panels. These boxes can be branded with the manufacturer’s logo, product information, and visual elements that align with the company’s overall aesthetics. By incorporating these branding elements, the packaging becomes an extension of the product itself, reinforcing brand identity and creating a memorable impression for customers.

In addition to custom boxes, manufacturers may opt for inserts or dividers designed to securely hold and protect individual shower glass panels within the packaging. These inserts can be made from various materials such as foam, molded pulp, or corrugated cardboard. The inserts are customized to fit the specific dimensions and contours of the glass panels, ensuring a snug and secure fit. This reduces the risk of movement and potential damage during transportation.

Protective coatings are another aspect of customized packaging. Manufacturers may apply specialized coatings to the glass panels to provide an extra layer of protection against scratches, abrasions, or fingerprints. These coatings can be transparent and virtually invisible, preserving the clarity and visual appeal of the glass while enhancing its durability.

Customized packaging solutions not only enhance the protection and presentation of the shower glass panels but also contribute to a positive customer experience. As packaging plays a crucial role in the overall perception of a product, well-designed and customized packaging can create a sense of value and quality for the customer. It demonstrates the manufacturer’s attention to detail and commitment to delivering a superior product.

Moreover, customized packaging can be tailored to specific customer preferences or project requirements. For example, architects, designers, or contractors may have unique packaging needs for large-scale projects or installations. Customized packaging allows for flexibility in meeting these demands and ensures that the glass panels arrive in pristine condition, ready for use.

Though customized packaging may involve additional costs and production time, it provides manufacturers with a competitive edge by offering a premium packaging solution that aligns with their brand image and meets the specific needs of their customers. By investing in customized packaging, manufacturers can elevate the overall product experience, strengthen customer satisfaction, and differentiate themselves in the market.

2. Factors that are needed in the packaging of shower glass doors

When choosing suitable foam materials for packaging shower glass doors, we must consider the following factors:

2.1 Foam Inserts

Many shower glass packages include foam inserts that are molded to fit the specific shape of the glass panels. These inserts provide excellent protection against shocks and vibrations, reducing the risk of damage during shipping.

2.2 Bubble Wrap

Bubble wrap is often used in combination with other types of packaging. It provides an additional layer of cushioning to protect shower glass from scratches and impacts. Bubble wrap is lightweight and flexible, making it easy to wrap around glass panels of various shapes and sizes.

2.3 Plastic Film

Clear plastic film is sometimes used to wrap individual shower glass panels. This helps protect the glass from scratches, dust, and moisture during transportation and storage. Plastic film is transparent, allowing customers to see the product without unwrapping it.

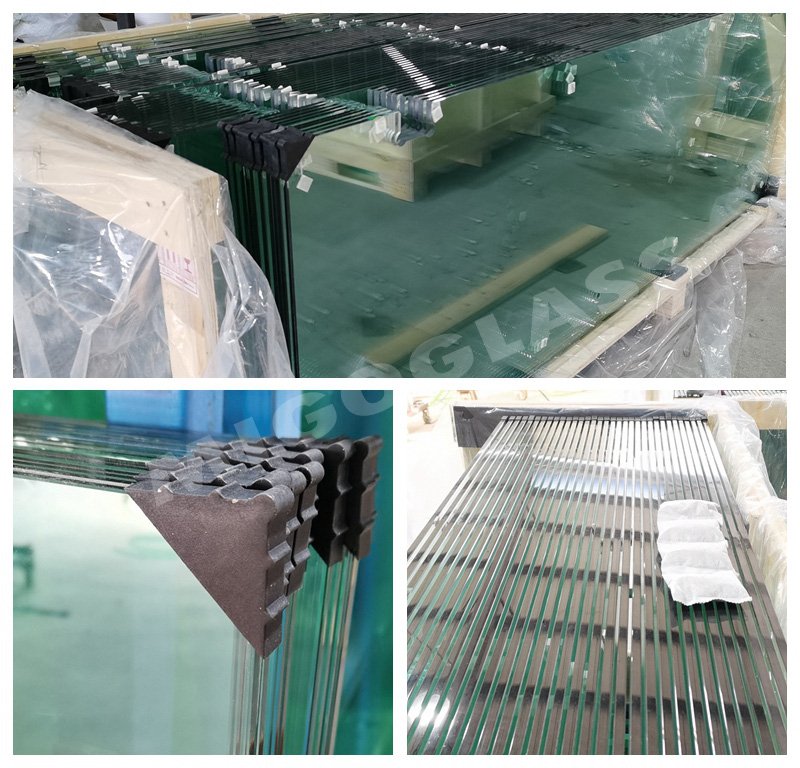

2.4 Edge Protectors

To safeguard the vulnerable edges of shower glass panels, edge protectors made of materials like foam or plastic are commonly used. These protectors are designed to fit securely over the edges, providing an extra layer of cushioning and preventing chipping or cracking during handling and transit.

2.5 Corner Protectors

Corner protectors are specifically designed to reinforce and protect the corners of shower glass panels. These braces are typically made of sturdy materials such as plastic or metal and are secured to the corners to provide added strength and stability, reducing the risk of damage during transportation.

2.6 Strapping or Stretch Wrap

To secure multiple glass panels together or to secure glass panels within their packaging, strapping or stretch wrap can be employed. These materials help to prevent shifting or movement during transit, ensuring that the glass panels remain in their intended position and reducing the chances of collision or damage.

2.7 Fragile Stickers or Labels

Packaging for shower glass panels often includes fragile stickers or labels. These labels serve as a visual reminder to handle the package with care and inform handlers that the contents are delicate and require gentle treatment. Fragile stickers or labels help to alert shipping personnel and encourage them to exercise caution during the transportation process.

3. Final Thoughts

In essence, the selection of packaging for shower glass hinges on factors like glass type, transportation mode, and the extent of protection required. MIGO Glass can safeguard shower glass’s integrity during transit by opting for suitable packaging materials and methods. By integrating additional packaging elements and materials, manufacturers can elevate protection levels, streamline convenience, and enrich the overall customer experience when handling and installing shower glass panels. Such initiatives underscore a dedication to product excellence, safety, and customer contentment, guaranteeing that the glass panels reach their destination in impeccable condition, primed for immediate use.