Mirrors hold an indispensable position in our daily lives, serving various purposes from personal grooming to scientific exploration. Among the plethora of mirrors available, two prominent types stand out: silver mirrors and copper-free silver mirrors. What Is the Difference Of Silver vs Copper Free Silver Mirror?

MIGO Shower Glass as a professional glass and mirror manufacturer for over 20 years, through our experience, even the two kinds of mirror appearance are very similar and both serve the fundamental function of reflection, but they are totally different mirrors. they diverge significantly in composition, manufacturing methodologies, and inherent properties. This article aims to dissect the intricate disparities between silver and copper-free mirrors, shedding light on their compositions, fabrication processes, and distinctive traits.

1. What Is Regular Mirror?

A regular mirror or regular silver mirror, also known as a two-way or one-way mirror, is a type of mirror with a thin layer of silver coating on its back surface. This coating allows light to pass through in one direction while reflecting light back in the opposite direction.

The term “two-way mirror” refers to the mirror’s ability to function differently depending on the lighting conditions on either side. When the lighting is brighter on one side and darker on the other, the side with the brighter lighting will appear reflective, like a typical mirror, while the side with the darker lighting will allow people to see through it.

Regular mirrors are commonly used in security settings, such as observation rooms, interrogation rooms, or surveillance setups, where the reflective side enables one-way observation. They are also used in theatrical performances, television studios, and special effects applications.

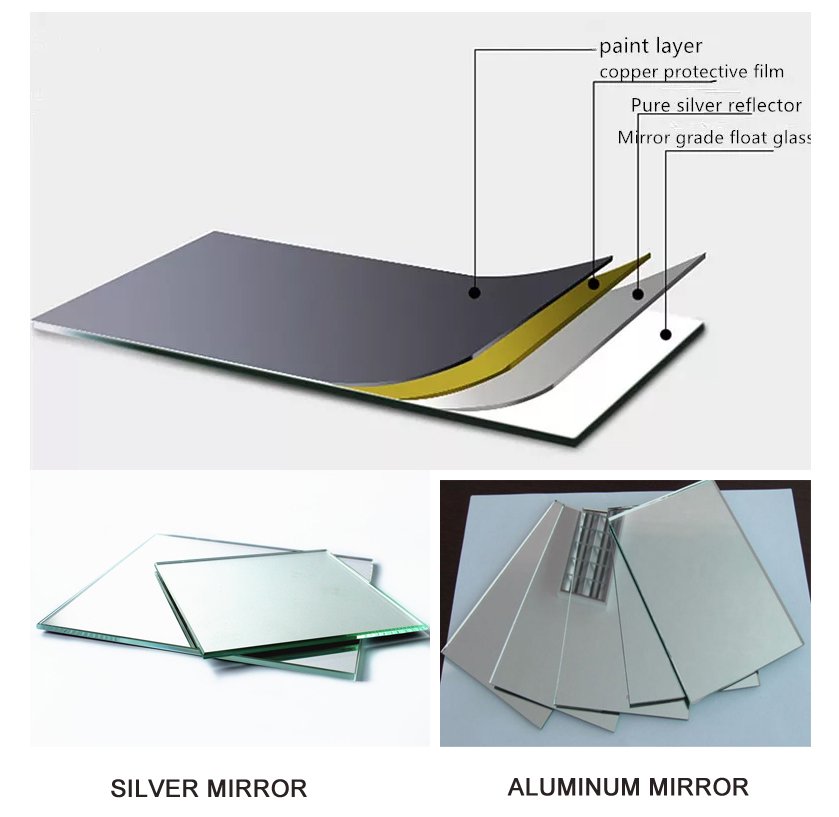

During the production process, a protective layer of copper is typically added to the silver coating to prevent oxidation and discoloration over time. The mirror is further protected by applying two layers of protective lacquer.

The creation of a regular mirror involves a chemical reduction process, where regular-ammonia compounds are chemically reduced, resulting in the deposition of metallic silver onto a carefully shaped glass surface, forming the reflective layer.

2. What Is Copper Free Silver Mirror?

A copper free silver mirror is a unique type of mirror that is manufactured without the incorporation of copper during its construction. Unlike traditional silver mirrors, which involve the use of copper in the process of applying a thin layer of silver onto a glass substrate, copper-free silver mirrors utilize alternative techniques to deposit the silver layer without the need for copper.

One prevalent method employed in the production of copper-free silver mirrors is a chemical sedimentation process. This involves the application of a specially treated silver sheet onto high-quality float glass. Instead of utilizing copper, a specialized metal film is employed as an intermediate layer between the glass and the silver. This metal film acts as a barrier, enhancing the adhesion of the silver layer to the glass surface.

To ensure the longevity and durability of the silver layer, two protective paint layers are added. These paint layers serve a dual purpose: they offer chemical resistance, safeguarding the mirror against potential damage caused by exposure to various substances, and provide physical protection, reducing the risk of scratches or other forms of harm.

Copper-free silver mirrors find applications in a wide range of settings, including residential and commercial environments, where superior reflectivity and clarity are desired. They possess similar reflective properties to those of traditional silver mirrors, but their manufacturing process eliminates the use of copper. This makes copper-free silver mirrors an attractive alternative for those seeking mirrors without copper components.

3. What Are The Similarities Of Regular Silver And Copper Free Silver Mirror?

Regular silver mirror and copper free silver mirror share several similarities despite their differences. Some of the similarities include:

3.1 Reflectivity

Both regular silver mirrors and copper-free silver mirrors are designed to provide high reflectivity. The silver layer in both types of mirrors allows for excellent reflection of light, resulting in clear and accurate reflections.

3.2 Base Material

Both types of mirrors typically use a glass substrate as the base material. High-quality float glass or low-iron glass is commonly employed to ensure a smooth and clear surface for the silver coating.

3.3 Manufacturing Process

While there are variations in the manufacturing process, both regular mirrors and copperfree silver mirrors undergo similar initial steps. These include cleaning and preparing the glass substrate to ensure a contaminant-free surface for optimal adhesion of the reflective layer.

3.4 Protective Coating

Regular mirror and copper free silver mirror require a protective coating to safeguard the reflective layer. In regular silver mirrors, a layer of copper is applied on top of the silver to protect it from tarnishing and corrosion. In copper-free silver mirrors, a different type of protective coating, such as silicon dioxide (SiO2) or other transparent materials, is applied to fulfill the same purpose.

3.5 Applications

Regular mirror and copper free silver mirror find application in various domains. They are widely used in residential and commercial settings as bathroom mirrors, decorative fixtures, and architectural installations. Both types of mirrors can also be utilized in the automotive industry for rear-view mirrors and other reflective components.

While there are notable differences between regular silver mirrors and copper-free silver mirrors, these similarities highlight their shared purpose of providing reflective surfaces for practical and aesthetic applications.

4. What Is The Difference Of Regular Silver vs Copper Free Silver Mirror?

The differences between regular silver mirrors and copper-free silver mirrors lie in their material composition, manufacturing process, properties, and characteristics. Here are the key distinctions:

4.1 Different Material Composition

Regular silver mirrors consist of a silver reflective layer with an additional protective layer of copper. On the other hand, copper free silver mirrors omit the copper layer and employ alternative protective coatings.

4.2 Different Manufacturing Process

Regular silver mirrors involve a process where a thin layer of silver is deposited onto the glass substrate, followed by the application of a copper layer. Copper-free silver mirrors use specialized techniques to directly deposit the silver layer onto the glass without the need for copper.

4.3 Different Reflectivity

Both regular silver mirrors and copper-free silver mirrors offer high reflectivity. However, copper-free silver mirrors may provide a slightly brighter reflection due to the absence of the copper layer.

4.4 Different Durability

Copper-free silver mirrors generally exhibit greater durability and resistance to tarnishing and corrosion compared to regular silver mirrors. The absence of the copper layer reduces the risk of tarnishing and oxidation over time, leading to an extended lifespan.

4.5 Different Environmental Impact

Copper free silver mirrors are considered more environmentally friendly compared to regular silver mirrors. The manufacturing process of regular silver mirrors involves the use of toxic chemicals like silver nitrate, which can have environmental hazards if mishandled. Copper-free silver mirrors eliminate the need for such chemicals, making them a more sustainable option.

4.6 Different Cost

In general, copper-free silver mirrors tend to be more cost-effective compared to regular silver mirrors. The omission of the copper layer reduces manufacturing costs and potentially lowers the overall price of the mirror.

4.7 Availability

Regular silver mirrors have a longer history and are more commonly available in the market. Copper-free silver mirrors, although gaining popularity, may have a more limited availability depending on the region and specific suppliers.

It’s worth noting that the differences mentioned above are general characteristics and may vary depending on the specific manufacturer and product. When choosing between regular silver mirrors and copper-free silver mirrors, considering factors such as desired durability, cost, environmental impact, and availability can help determine the most suitable option for your needs.

4. Summary

Regular mirrors and copperfree silver mirrors epitomize two distinct paradigms in the realm of reflective surfaces, each characterized by its unique composition, manufacturing techniques, and intrinsic attributes. While silver mirrors exude elegance and offer exemplary reflectivity, However, the use of copper components in the manufacturing process of silver mirrors also has a negative impact on the environment. Therefore, copper-free silver mirrors avoid copper components during the manufacturing and use processes, making them more environmentally friendly and enhanced environmental sustainability.

The selection between silver and copper-free silver mirrors hinges upon the specific requisites of the application, budgetary considerations, and individual predilections. As technological advancements burgeon, novel materials and methodologies may continue to shape the landscape of mirror fabrication, ushering in a panoply of options and prospects for reflection.