1. Introduction

Every salesperson knows that closing deals with new customers is a journey full of challenges. The story I want to share today is exactly such a process from unfamiliarity to trust, from exploration to winning orders.

1.1 First acquaintance: Inquiries for new customers and new products

A few months ago, the company received an inquiry from a new French customer for self-cleaning bathroom glass. We are keenly aware that this product is the most competitive product in the bathroom field today. At the same time, we have also conducted a detailed background check on the customer. The customer is a manufacturer and brand owner with many years of experience in the bathroom field and has designed multiple bathroom product series. , is currently laying out the market for bathroom self-cleaning products, so the customer decided to choose suppliers from China to enhance its competitiveness in the market at more favorable prices. To sum up, this customer is our proper target customer. Self-cleaning bathroom glass is also a popular product at the moment. We should seize this opportunity and master the processing requirements and technical characteristics of the new product in the process of cooperating with the customer. , enhance the company’s competitiveness.

1.2 Digging deeper: the deep needs behind customers

Through communication with the customer, we learned that the customer had inspected different Chinese suppliers before, but after testing the samples, the product could not meet the customer’s requirements, so the customer also contacted MIGO GLASS after multiple inspections, and the customer also Have an understanding of our company’s development and products. We communicated the company’s size and development philosophy to customers through multiple phone calls and emails, and used our professional knowledge, service concepts, and cooperation experience with many well-known brands in the industry to convince customers and gradually build a trusting relationship with customers.

After that, the customer provided us with the drawings and technical parameters of the self-cleaning bathroom glass. The company established a technical team for self-cleaning bathroom glass to study the current international information on this product and combine it with our production equipment and processing technology. Discuss possible solutions for the production and processing of clean bathroom glass.

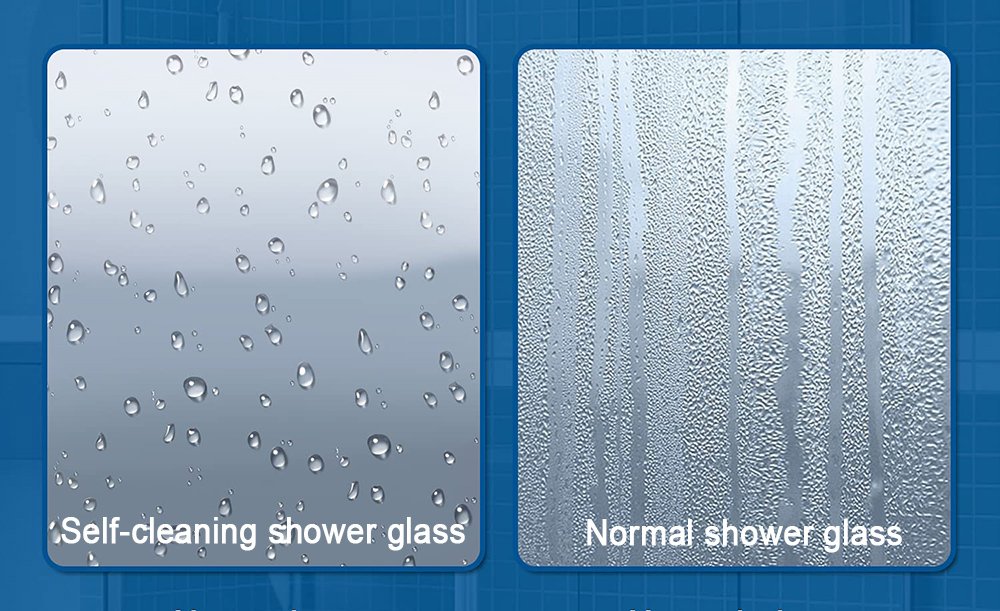

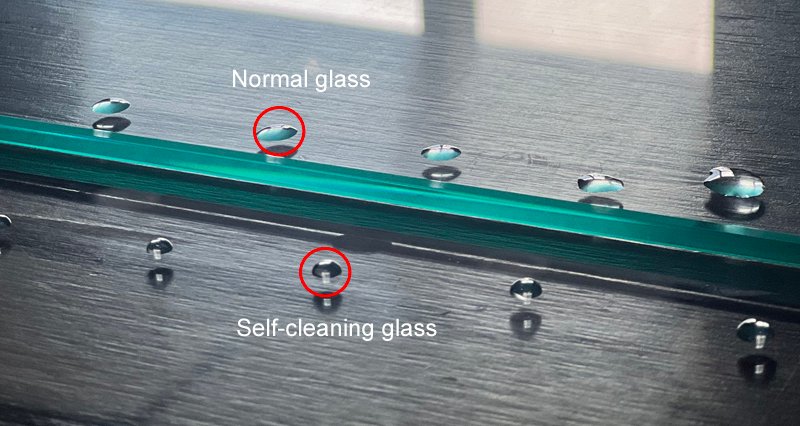

In the process, we learned what self-cleaning glass is, the characteristics of self-cleaning glass, the difference between self-cleaning glass and ordinary bathroom glass, as well as the processing requirements and related standards of self-cleaning glass.

2. Understanding Self-Cleaning Coatings

A self-cleaning coating is a transparent shield that can be applied to glass or ceramic surfaces, creating a tough and long-lasting water-repellent and self-cleaning surface. It is also named Easy Clean, Stay Clean Protective Glass, etc. It is a nanotechnology, in combination with the remarkable properties of lotus leaves, that has led to the development of this extraordinary product.

Although glass may appear smooth, it has microscopically pitted surfaces that tend to attract and retain dirt, grime, dust, bacteria, calcium, and other deposits. There are primarily two main mechanisms by which self-cleaning coatings work:

2.1 Photocatalytic Coatings:

These coatings utilize semiconductor materials like titanium dioxide (TiO2) that can generate highly reactive oxygen species when exposed to light, especially UV light. The reactive oxygen species can break down and decompose organic contaminants on the surface, effectively “cleaning” the glass. The photocatalytic reaction continues as long as the coating is exposed to light, making it a self-renewing cleaning process.

2.2 Hydrophilic Coatings:

These coatings modify the surface energy of the glass to make it highly hydrophilic (water-loving).

When water comes into contact with the surface, it forms a continuous, thin water film instead of beading up. This water film can effectively wash away dirt, grime, and other contaminants, leaving the surface clean. The hydrophilic nature is maintained over time, sustaining the self-cleaning properties.

The shower enclosures feature nano-coating, which works in two stages. The first stage is a photocatalytic reaction caused by ingredients in the coating. These interact with dirt and light and break down the filth you leave behind you.

Second is a hydrophilic coating which attracts water. Instead of running off in droplets, the water “hits the glass and spreads evenly,” taking the newly freed dirt with it. According to the press blurb, the only thing you need to do is give the screen a quick spray with the shower head after you’re done showering, and it’ll stay “pristine and sparkling.”

3. Reduced Cleaning Effort

How self-cleaning coatings can significantly reduce the frequency and effort required for manual cleaning of shower glass?

To demonstrate how self-cleaning coatings can significantly reduce the frequency and effort required for manual cleaning of shower glass, let’s consider a hypothetical scenario:

3.1 Scenario

A homeowner has a shower enclosure with standard, uncoated glass. They typically need to clean the shower glass once a week to maintain its appearance and hygiene. This involves the following steps:

- Removing any visible dirt, grime, and soap scum using a squeegee and cleaning solution

- Wiping down the glass to ensure a streak-free finish

- Disposing of the used cleaning materials

3.2 Self-Cleaning Coatings Scenario:

After applying a self-cleaning coating to the shower glass, the homeowner finds that the frequency of manual cleaning can be reduced to once every 4-6 weeks. The steps involved are:

- A quick wipe-down with a damp cloth to remove any loose debris

- No need for extensive scrubbing or the use of harsh cleaning solutions

4. Production of self-cleaning shower glass

The production of self-cleaning shower glass typically involves the following steps:

4.1 Cutting and Edging

- Custom Sizing: The glass is cut to the required size for shower enclosures.

- Edge Finishing: Edges are polished or beveled to ensure safety and enhance the aesthetic appeal.

4.2 Surface Preparation

- Cleaning: The glass surface must be thoroughly cleaned to remove any dirt, grease, or contaminants. This ensures the coating adheres properly.

- Drying: The glass is dried to remove any residual moisture, which could interfere with the coating process.

4.3 Coating Application

- Chemical Coating: A thin layer of a hydrophilic and photocatalytic material, often titanium dioxide (TiO2), is applied to the glass surface.

- Application Methods:The coating can be applied using methods such as chemical vapor deposition (CVD), spray coating, or dipping.

- Thickness Control:The coating is usually very thin, often in the nanometer range, to maintain the glass’s transparency while providing the self-cleaning properties.

- Heat Treatment:The coated glass is often heated to a specific temperature to cure the coating and ensure it bonds properly to the glass surface.

4.4 Quality Control

- Inspection:The glass is inspected for uniformity in coating, transparency, and any defects like bubbles or streaks.

- Testing: Tests are conducted to ensure the coating’s durability, effectiveness in repelling water, and resistance to wear and chemicals.

5. Benefits of self-cleaning shower glass

5.1 Time and Cost Savings:

- Frequency of Cleaning Reduced: From once a week to once every 4-6 weeks, a reduction of 75-83%.

- Time Savings: With less frequent cleaning, the homeowner saves approximately 3-4 hours per month in cleaning time.

- Cost Savings: The reduced need for cleaning supplies and materials can result in an annual cost saving of $50-$100 or more, depending on the specific products used.

5.2 Improved User Experience:

- Consistent Cleanliness: The self-cleaning coatings help maintain the shower glass in a cleaner state, improving the overall user experience.

- Reduced Effort: The homeowner spends significantly less time and effort on manual cleaning, freeing up time for other household tasks or leisure activities.

- Longer Lifespan: The self-cleaning coatings can help extend the lifespan of the shower glass by preventing excessive wear and tear from frequent cleaning.

5.3 Environmental Benefits ( Eco Friendly)

Self-cleaning coatings for shower glass offer several eco-friendly benefits through their ability to reduce the use of cleaning products and water consumption.

5.3.1 Reduced Use of Cleaning Products:

Traditional manual cleaning of shower glass typically involves the use of various cleaning solutions, detergents, and chemicals. Self-cleaning coatings, on the other hand, significantly minimize the need for these harsh cleaning products. With less frequent manual cleaning required, the homeowner can avoid the regular purchase and use of chemical-based cleaning supplies.

5.3.2 Decreased Water Consumption:

Manual cleaning of shower glass often involves the use of water to rinse away dirt, grime, and cleaning solutions. Self-cleaning coatings can reduce the overall water consumption required for maintaining the cleanliness of the shower glass. The continuous water film formed on the hydrophilic surface, combined with the self-cleaning mechanisms, allows for more efficient cleaning with less water usage.

5.3.3 Longevity and Waste Reduction:

Self-cleaning coatings can help extend the lifespan of the shower glass, reducing the frequency of replacement and the associated waste generation. Fewer replacement cycles mean less material and energy consumption for manufacturing new shower glass, contributing to a more sustainable product lifecycle.

6. Conclusion

Overall, self-cleaning coatings provide a convenient and effective solution for maintaining the cleanliness of shower glass with minimal effort. We strongly advise considering glass surface protection as an investment to preserve the brilliance of your glass doors and minimize the need for cleaning. By doing so, you can also extend the lifespan of your shower doors. Fab Glass and Mirror offers a variety of shower coating options to improve the strength and endurance of your glass shower doors. MIGO Shower Glass offers a variety of shower quality coating options to maximize the durability value of your glass shower doors, with warranties of 5 years and 10 years. Additionally, our factory utilizes an automatic machine treatment on the glass to ensure a more uniform quality.