A glass mirror is a reflective surface created by coating glass with a thin layer of metal, usually silver or aluminum. Glass mirrors are widely utilized in bathrooms, bedrooms, and dressing rooms for personal grooming and self-assessment. They exist in a range of shapes and sizes, with options for both framed and frameless designs. Beyond practical use, glass mirrors find application in decorative contexts, including art installations, furniture, and interior design, enhancing aesthetics and functionality.

As the custom glass mirror manufacturer and supplier, MIGO Glass offers various glass mirrors including siver mirror and copper free mirror in custom thickness and sizes at competitive factory prices. In this blog, let us explore silver and aluminum mirrors definitions and differences. We hope it will help you choose the right glass mirror for your specific decorations.

1. What Is Silver Mirror?

A silver mirror is crafted by depositing a thin layer of silver onto a glass surface, resulting in a mirror with exceptional reflectivity. The silver coating grants silver mirrors the ability to deliver a superior level of reflection, making them well-suited for applications that demand high-quality reflections. They find extensive use in decorative mirrors, scientific instruments, and optical devices.

Compared to other mirror types, silver mirrors excel in providing clarity and reflectivity. However, their production cost tends to be higher due to the use of silver. The hallmark of silver mirrors lies in their ability to produce bright and clear reflections, making them a favored choice in settings that prioritize image quality. Whether adorning elegant interiors or facilitating precise scientific measurements, silver mirrors stand as a premium option, offering impeccable reflection quality and enhancing visual appeal.

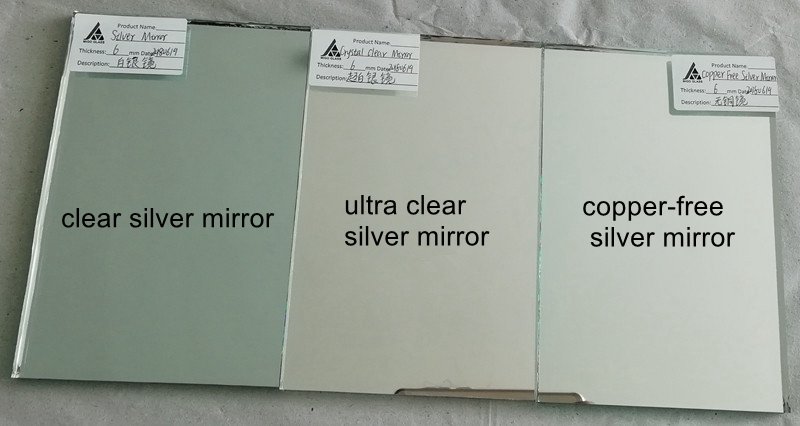

Common Silver Mirror types:

| Clear Silver Mirror (made of clear float glass) |

Ultra clear silver mirror (made of ultra clear low iron float glass) | |

Grey silver mirror | |

Bronze silver mirror | |

Copper free silver mirror | |

Vinyl Backed safety silver mirror (shatterproof) |

2. What Is Aluminium Mirror?

An aluminum mirror is made by coating a glass surface with a thin layer of aluminum.

This aluminum coating provides a reflective surface that is similar to a silver mirror, but it is typically less expensive to produce. Aluminum glass mirrors are commonly used in residential and commercial settings, such as bathrooms, bedrooms, and dressing rooms. They offer good reflectivity and durability, making them a popular choice for everyday use. However, aluminum mirrors may not provide the same level of clarity and brightness as silver mirrors. Overall, aluminum glass mirrors are a cost-effective option for those looking for a functional and affordable mirror solution.

Common Aluminum Mirror types:

| Clear Aluminum Mirror (made of clear float glass) |

Grey Aluminum mirror | |

Bronze Aluminum mirror | |

Vinyl Backed Aluminum mirror (shatterproof) | |

Convex/concave Aluminum Mirror |

3. What is Difference of Silver Mirror vs Aluminum Mirror?

There are several key differences between silver mirrors and aluminum mirrors:

3.1 Different Production Process

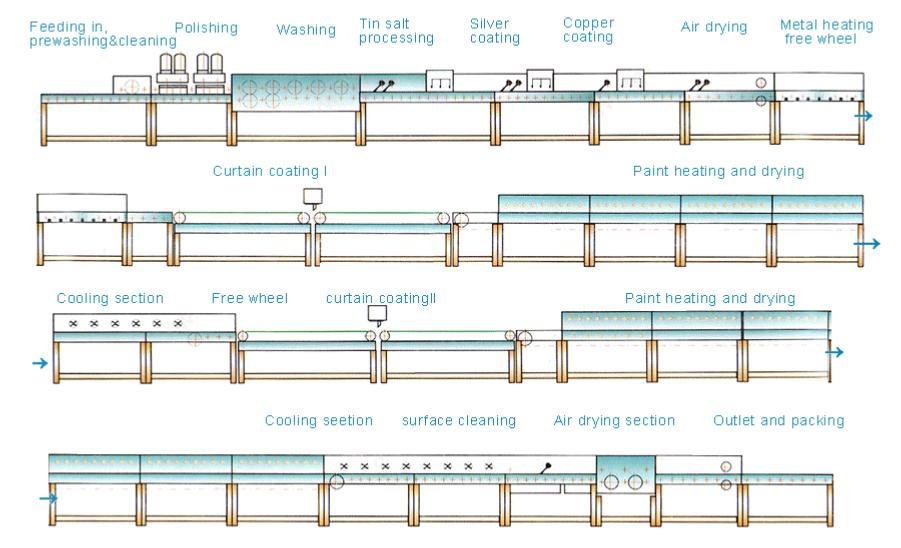

The production process of silver mirrors is much more complex than aluminium mirrors.

The production of silver mirrors is a chemical reaction process, while the production of aluminum mirrors is a physical process. Please refer to below production flows of the silver mirror and Aluminium mirror.

Below is the Production flow of Silver Mirrors

Below is the Production flow of Aluminium Mirrors

3.2 Different Raw material

3.2.1 Substrate Glass

Substrate glass material is the same to produce silver mirror and aluminium mirror.

Substrate glass grade must use Mirror grade instead of average building glass grade quality.

Substrate glass won’t allow scratches, bubble, stone, string, etc.

3.2.2 Reflective coating

The material used for the reflective layer is different.

Silvering process: A thin layer of silver is deposited onto the glass substrate using a chemical reaction. The silvering process involves the reduction of a silver salt solution, which results in the deposition of metallic silver onto the glass surface.

Aluminium deposition: Instead of using silver, a thin layer of aluminium is deposited onto the glass substrate using a process called physical vapor deposition (PVD). In this process, aluminium atoms are evaporated and then condensed onto the glass surface to form a reflective layer.

3.2.3 Back paint coating

Silver mirrors are typically protected by multiple layers of paint. To determine if a mirror is silver or aluminum, scratch off a portion of the protective paint on the surface. If the bottom layer reveals a copper color, it is a silver mirror. If it shows a silvery white color, it is an aluminum mirror. In general, the back coating of silver mirrors is dark gray, while the back coating of aluminum mirrors is light gray.

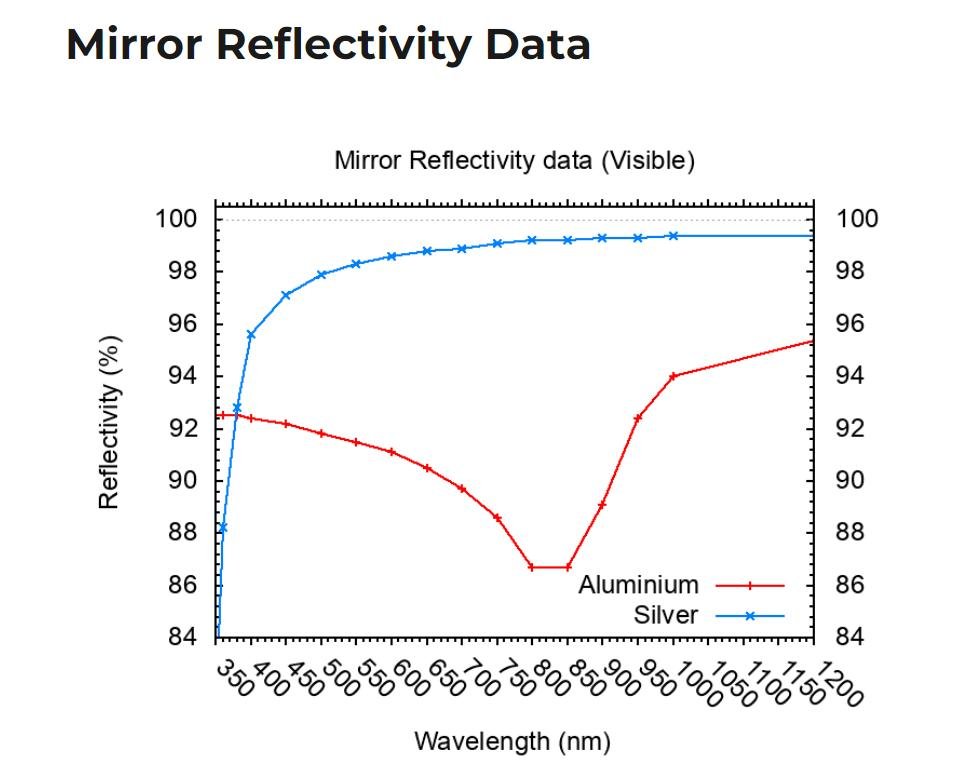

3.2.4 Reflectivity levels

Silver mirrors generally have higher reflectivity levels compared to aluminum mirrors. Silver has a higher reflectivity in the visible light spectrum, which means that silver mirrors can reflect more light and produce brighter and clearer images.

The reflectivity of aluminum mirror is low, moreover, the shape and color are easy to be distorted, and the life is short, the corrosion resistance is poor, and it has been completely eliminated in European and American countries.

3.3 Different Durability and Longevity

Silver is a passive metal, whereas aluminum is a reactive metal. Over time, aluminum will oxidize and lose its color, turning gray, but silver will not undergo this change. Testing with dilute hydrochloric acid can easily demonstrate this difference. The reaction of aluminum is vigorous, while silver’s reaction is much slower. Silver mirrors are more resistant to water and moisture compared to aluminum mirrors, providing clearer and brighter reflections. They are commonly used in moist environments like bathrooms and are more long-lasting than aluminum mirrors.

3.4 Different Cost comparison

Silver mirrors are typically more expensive than aluminum mirrors due to the higher cost of silver as a raw material. Silver is a precious metal with a higher market value compared to aluminum, which is a more common and less expensive metal. The production process of silver mirrors also involves additional steps and materials compared to aluminum mirrors, further contributing to the higher cost.

Aluminum mirrors are a more cost-effective option for those looking to save money on mirror purchases. They are commonly used in commercial settings or large-scale projects where cost considerations are important. However, it’s important to note that aluminum mirrors do not have the same level of reflectivity or longevity as silver mirrors.

Ultimately, the choice between silver and aluminum mirrors will depend on your budget, the intended use of the mirror, and your preferences for reflectivity and durability.

4. How To Choose Right Glass Mirror Between Silver Mirror vs Aluminum Mirror?

When deciding between a silver mirror and an aluminum mirror, various factors come into play, such as durability, reflectivity, cost, and environmental considerations. Here’s a breakdown to assist you in making the right choice:

4.1 Silver Mirror:

Pros:

- Superior Reflectivity: Reflects 95% of light, resulting in a clearer and sharper image.

- Durability: More resistant to moisture and corrosion, making it suitable for bathrooms and humid environments.

- Longevity: With proper care, a silver mirror can last for many years.

Cons:

Higher Cost: Generally, silver mirrors are more expensive compared to aluminum mirrors.

4.2 Aluminum Mirror:

Pros:

Affordability: An economical option when compared to silver mirrors.

Cons:

- Lower Reflectivity: Reflects around 90% of light, leading to a slightly less vibrant image.

- Lesser Durability: More susceptible to moisture damage and corrosion, making it less ideal for bathrooms or high-humidity areas.

- Shorter Lifespan: May require replacement sooner than a silver mirror.

From the glass mirror manufacturer’s view, MIGO Glass give your the following recommendations.

If you prefer the following aspects, you can choose a silver mirror.

- Image quality and clarity are a top priority.

- The mirror will be placed in a bathroom or a humid environment.

- Durability is crucial, and you intend to keep the mirror for an extended period.

If you prefer the following aspects, you can choose an aluminum mirror:

- You have budget constraints.

- Image quality is not a major concern.

- The mirror will be installed in a dry location with minimal exposure to moisture.

Additional factors to consider:

- Size and weight: Silver mirrors are generally heavier than aluminum mirrors of the same size.

- Aesthetics: While both silver and aluminum mirrors offer reflective surfaces, some individuals may prefer the subtle difference in reflectivity provided by silver mirrors.

5. Conclusion

In summary, silver mirrors offer higher reflectivity and a longer lifespan compared to aluminum mirrors. They are a premium option that provides a clearer and more accurate reflection, making them ideal for high-end residential or commercial settings where image quality is important. Silver mirrors also have a more luxurious appearance and are often chosen for their aesthetic appeal.

On the other hand, aluminum mirrors are a more cost-effective alternative that still provide decent reflectivity for everyday use. They are commonly used in budget-friendly projects or applications where cost is a primary concern. Aluminum mirrors are lightweight and easy to install, making them a practical choice for large-scale projects or temporary installations.

Ultimately, the choice between silver and aluminum mirrors will depend on your specific needs, budget, and preferences. Consider factors such as reflectivity, durability, cost, and aesthetic appeal when deciding which type of mirror is best suited for your project.