Aluminum, silver, and copper-free mirrors are the most used types on the market. These mirrors are indeed an essential part of our daily lives, serving various purposes such as grooming, decoration, and reflecting light. You need to understand the specific kind of mirror they intend to purchase, as the cost may vary based on factors such as durability and imaging effects. The processing method behind an aluminum, silver and copper-free mirror and the reasons for different costs among various types of mirrors are worth discussing. One significant factor contributing to cost differences is the coating used. Each type of mirror has its own unique characteristics and advantages, making them suitable for different applications, which in turn influences their prices.

As a reliable mirror manufacturer and supplier, MIGO Glass offers a wide range of custom aluminum mirrors, silver mirrors, and copper-free mirrors for global brands in bulk orders at competitive factory prices.

In this blog, let us delve into the details of three major types of mirrors: aluminum mirrors, silver mirrors, and copper-free mirrors.

1. What Is Aluminum Mirror?

An aluminum mirror is a type of mirror that is made from aluminum or aluminum alloys instead of glass. It is commonly used in applications where weight is a concern, such as in aerospace, defense, and medical optical systems.

Aluminum mirror is popular for their lightweight properties, making them suitable for use in scanning mirrors and galvo mirrors. They offer an alternative to traditional glass mirrors, providing a lighter and more compact solution for optical systems.

Aluminum mirror has some limitations compared to glass mirrors. The reflective ratio of an aluminum mirror is around 70%, which is slightly lower than that of a glass mirror. Additionally, the reflected shapes and colors can be easily altered with an aluminum mirror, which may not be desirable in certain applications where accurate reflection is important.

Aluminum mirrors have a shorter lifetime and are more susceptible to corrosion compared to silver mirrors. Silver mirrors, on the other hand, offer a more realistic and darker reflection and have a longer lifespan.

While aluminum mirrors offer advantages in terms of weight and compactness, they may not provide the same level of reflective quality or durability as glass or silver mirrors. The choice between aluminum and other mirror materials depends on the specific requirements of the application and the desired performance characteristics.

2. What Is Silver Mirror?

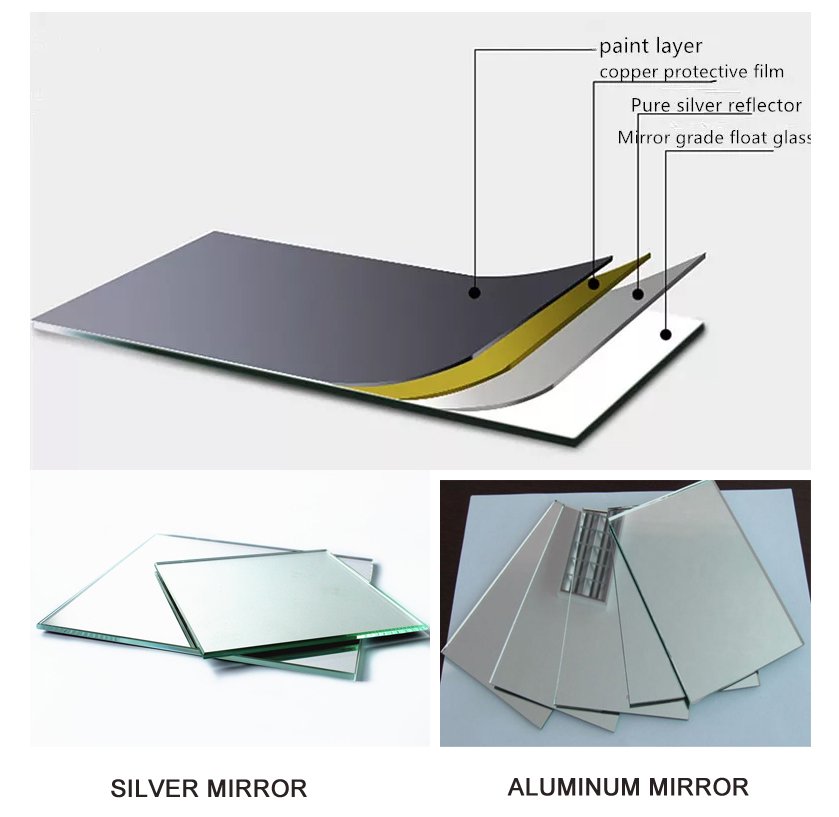

A silver mirror, also known as a silver glass mirror, is a type of mirror that is commonly used in various applications such as furniture, arts and crafts, decoration, bathroom mirrors, cosmetic mirrors, optical mirrors, and car rearview mirrors. It is created by coating the back surface of the glass with a thin layer of silver, which allows for reflection and the production of clear images.

The process of creating a silver mirror involves coating the glass with a silvering solution, which results in the deposition of a thin layer of silver onto the glass surface. This silver layer acts as the reflective surface, allowing the mirror to reflect light and produce clear and accurate reflections.

Compared to aluminum mirrors, silver mirrors provide higher reflectivity and clarity. The silver coating offers a more realistic and darker reflection, making it a preferred choice for applications where accurate reflection is important.

When storing silver mirrors, it is essential to avoid stacking them with alkaline and acid substances and to keep them away from humid environments. This helps to maintain the integrity of the silver coating and prolong the mirror’s lifespan.

In summary, a silver mirror is a type of mirror that is coated with a thin layer of silver on the back surface of the glass. It offers high reflectivity, clarity, and durability, making it a popular choice for a wide range of applications.

3. What Is Copper Free Mirror?

A copper free mirror, also known as a lead-free mirror, is a modern type of mirror that is manufactured without the use of copper or lead. Unlike traditional mirrors, copper-free mirrors are resistant to humidity and corrosion due to the absence of copper in their manufacturing process.

Copper free mirror offers excellent features such as clear imaging, high reflectivity, high brightness, and good color reproduction. They are designed to provide a durable and long-lasting mirror solution for various applications.

The production of copper-free mirrors involves a chemical deposition process. A layer of specially treated silver is applied to high-quality float glass. Instead of using copper, a special metallic film that is low or completely free of lead and copper is applied. To provide additional protection, two layers of paint are applied to the back side of the mirror, preventing corrosion spots and scratches, similar to glass coatings.

Copper free mirrors are environmentally friendly. By eliminating the use of copper and lead, these mirrors contribute to a cleaner and safer environment.

Copper-free mirrors are the latest innovation in mirror manufacturing. They offer exceptional clarity, reflectivity, brightness, and color reproduction. With their resistance to humidity and corrosion, these mirrors provide a durable and environmentally friendly solution for various applications.

MIGO Glass manufactures and supplies OEM/ODM copper-free mirrors in custom thickness and size for global brands.

4. What Is the Difference Of Aluminum, Silver, And Copper Free Mirror

4.1 What Is Mirror Coating?

Glass mirrors are commonly found in bathrooms due to their reflective properties. Mirrors reflect light in such a way that they reverse the image and allow viewers to see themselves, objects behind them, or even objects at different angles that are outside their direct line of sight, such as around corners. This unique property of mirrors enables individuals to have a broader perspective and observe things that would otherwise be out of their field of view.

Mirror coating is a process by which a layer is deposited onto the surface of glass to enhance its reflective properties. This coating is what gives mirrors their ability to reflect light and produce clear images. The mirror coating can improve the mirror’s reflective qualities, especially for specific colors or wavelengths of light.

When the coating is applied to the glass surface, it creates a reflective surface that allows light to bounce off and create a reflection. The thickness and composition of the coating can affect the mirror’s reflectivity and the specific colors that are reflected. Mirror coatings are designed to maximize reflection and minimize light absorption, resulting in a highly reflective surface.

Mirrors with a proper mirror coating are widely used in decoration, as well as in various industries where reflective surfaces are needed. The coating enhances the mirror’s ability to reflect light and provides a clear and accurate reflection. This makes mirrors an essential component in many applications, from home decor to scientific instruments.

The primary component of mirror coatings is metal plating, which involves depositing metals such as gold, platinum, silver, and copper onto the surface of the glass. However, this does not imply that one can simply weigh a mirror and sell it based on the value of the metal it contains. Differnt types of mirror may have differenty layers of coating, all of the basic is the mirror grade float glass. However, some of the customers may see the scratches and bubbles, the one of reasons may come from the raw material of the float glass, which may not be mirror grade, this is one of part of the cheap mirror comes from.

4.2 Why Is Mirror Coated?

Mirror is glass sheet coated with silver. The coating is what makes the mirror a mirror. If there’s no coating, light would pass through the “mirror” because it would be transparent. The silver coating is opaque and therefore reflects light very brilliantly and is responsible for forming images.

The coating helps to protect the reflective surface of the mirror from corrosion and degradation. This is especially important in environments where the mirror is exposed to moisture, chemicals, or other corrosive substances. The coating acts as a barrier, preventing these substances from reaching the reflective surface and causing damage.

Enhance the reflective properties of the mirror. By applying a specialized coating, the mirror can achieve a higher level of reflectivity, resulting in clearer and more accurate reflections. This is particularly important in applications where precise reflection is required, such as in optical instruments or scientific equipment.

Improve the durability of the mirror. By providing a protective layer, the coating helps to extend the lifespan of the mirror, reducing the need for frequent replacement and maintenance. This is particularly beneficial in commercial and industrial settings where mirrors are subjected to heavy use and wear. Better coating you will not see the black spots for over years.

4.3 Differences Of Aluminum, Silver And Copper Free Mirror

Aluminum mirrors are lightweight but have lower reflectivity. Silver mirrors offer higher reflectivity and a more realistic reflection. Copper-free mirrors excel in durability, reflectivity, and environmental friendliness. The choice of mirror type ultimately depends on specific requirements, such as the need for lightweight construction, higher reflectivity, or environmental considerations.

4.3.1 Aluminum Mirror, Cost-Efficient and budget-friendly option

Aluminum mirrors are manufactured using a thin aluminum film deposited on a clear glass substrate. Aluminum mirrors, with a reflectivity of only 90%, produce reflections that are less vivid and colors that appear muted. Although a more cost-effective option, these mirrors often suffer from waviness and feature a thinner coating that makes them susceptible to scratches.

Due to aluminum’s higher reactivity compared to silver, it quickly oxidizes when exposed to moisture, making it less ideal for use in bathrooms or outdoor settings. The major thickness like 2mm, 3mm and 4mm.

However, Aluminum mirrors are generally more affordable than silver mirrors, making them a cost-effective option for those on a budget. Also, aluminum mirror are lighter in weight compared to silver mirror, making them easier to handle and install. The most important aluminum has more corrosion resistance since the aluminum is natuallly corrosion-ressitant, forming a protective oxide layer on its surface that helps prevent rust and deterioration.

Applicaiton: Automotivve mirror , residental mirror ,industrial mirror and etc

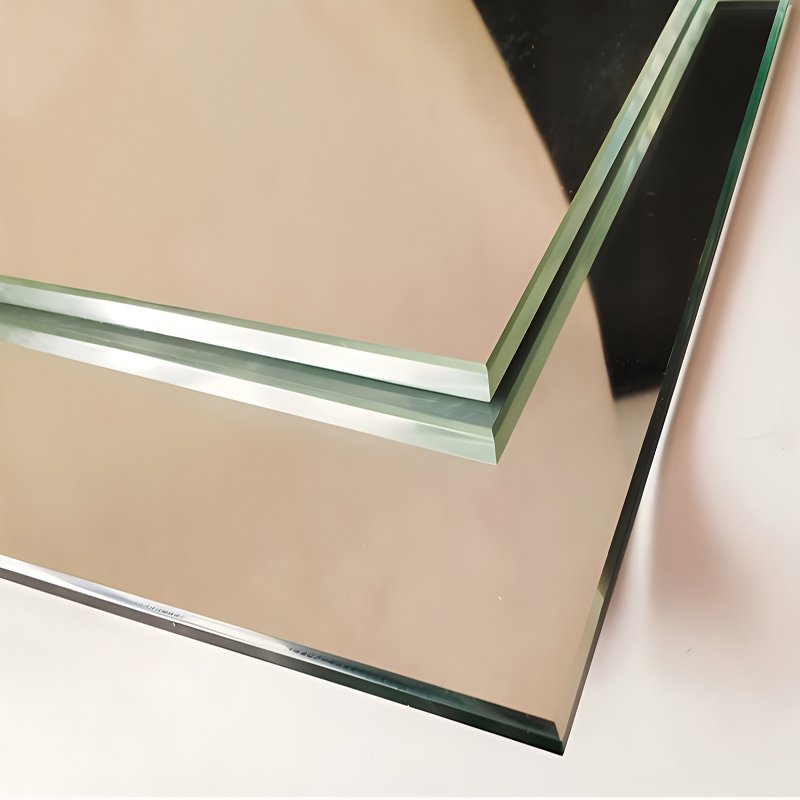

4.3.2 Silver Mirror, popular and efficient choice

Silver mirrors are crafted by depositing a thin layer of silver onto a glass substrate. Silver mirrors have become increasingly popular among women as they can reflect up to 95% of the light spectrum, producing vibrant reflections and richer hues. Despite being more expensive, they are the favored choice for most consumers and are now synonymous with quality in the mirror industry. Their thicker silver-coated layers make them more resistant to rust compared to aluminum mirrors. Even when exposed to strong chemicals during cleaning, they have a longer lifespan. With proper maintenance, silver mirrors can retain their condition for up to three years without oxidizing, making them a durable option for home decor and bathroom mirrors. As a result, silver-coated mirrors have become a staple product in most markets, providing both aesthetic appeal and longevity. The major thickness like 4mm, 5mm, and 6mm.

The primary advantage of silver mirrors lies in their superior reflectivity, which results in clear and distortion-free reflections. Silver mirrors are favored for their ability to produce high-quality images with minimal light loss. However, silver mirrors are susceptible to tarnishing and corrosion when exposed to moisture and air. As a result, they require careful handling and maintenance to preserve their reflective properties.

Application: Hotel bathroom, decorative mirror, laser system, scientific instrument, industrial mirror etc.

4.3.3 Copper free mirror- Environmental ,high durable, and premium choice

Copper-free mirrors, also known as environmentally friendly mirrors, are designed to address the environmental concerns associated with traditional mirror manufacturing processes with a lead content of <1 ppm . Unlike aluminum and silver mirrors, copper-free mirrors utilize advanced technologies to eliminate the use of copper and other harmful substances in their production. By utilizing alternative materials and manufacturing methods, copper-free mirrors offer a sustainable and eco-friendly alternative to conventional mirrors.

The key advantage of copper-free mirrors lies in their eco-friendly nature, making them a preferred choice for environmentally conscious consumers and businesses. These mirrors are manufactured using innovative techniques that minimize environmental impact while maintaining high reflectivity and optical quality. Copper-free mirrors are made out of the silver coating as its main reflective material, which allows them to give that vibrant reflection that women love so much from the Silver Mirror. From Migo glass’ mirrors, we incorporate an additional antioxidant layer to provide extra protection against corrosive chemicals, moisture, and water, ensuring the mirror remains in top condition for longer.

Application: Luxuray hotel bathroom, medical and dental equipement, laboratory setting, dispaly cases and etc

5. Conclusion

The differences between aluminum, silver, and copper-free mirrors are quite distinct. Aluminum mirrors are lightweight but have lower reflectivity. Silver mirrors provide higher reflectivity and a more realistic reflection. Copper-free mirrors offer durability, excellent reflectivity, and are environmentally friendly. The choice of mirror type depends on specific requirements, such as weight, reflectivity, and environmental considerations.

Most important, aluminum and silver mirrors typically last around 12-24 months before corrosion spots start to appear. In contrast, copper-free mirrors are designed to prevent corrosion and are three times more resistant to it than traditional mirrors. This increased resistance ensures that copper-free mirrors have a longer lifespan, making them a durable and reliable choice. If you pick a mirror with a poor-quality coating, then your mirror surface will have black spots and mold in 1 to 2 years. So copper-free mirrors are your best choice.

Any questions or inquiries, please contact Migo Glass for detailed information.