Glass is a remarkable material that finds extensive use in various industries and applications, from construction to interior design, automotive, electronics, and more. Its versatility lies not only in its transparency and aesthetic appeal but also in its ability to be shaped and customized to fit specific needs. One crucial aspect of glass customization is the edge treatment; the different types of glass edge finishes enhance the appearance and improve safety and functionality.

As the leading glass manufacturer and supplier, MIGO Glass offers custom shower glass at the best factory price in bulk orders. In this ultimate guide, we’ll delve into the various types of glass edge finishes, their characteristics, applications, and the benefits they offer.

1. What Are Types of Glass Edge Finishes?

Glass edge finishes are a critical aspect of customizing glass, as they impact both the appearance and functionality of the final product. Glass edging involves the process of grinding and shaping the raw and jagged corners of glass to achieve a smooth and polished texture.

There are several types of glass edge finishes available, each serving its own purpose. These finishes not only enhance the visual appeal of the glass but also contribute to safety and functionality. For instance, a flat polished edge provides a clean and professional look, while a beveled edge adds a decorative touch. A seamed edge is commonly used for hidden or framed glass, ensuring a safe and smooth finish without the need for additional polishing.

The choice of edge finish depends on various factors, including the specific application, desired aesthetic, and functional requirements. By selecting the appropriate edge finish, you can achieve the desired look and performance for your glass. Consulting with glass fabricators or suppliers can provide valuable insights and assistance in choosing the most suitable edge finish for your project.

Glass edge finishes are integral to the customization process, enhancing the appearance, safety, and functionality of the glass. Understanding the available options and considering your specific requirements will help you make an informed decision when selecting the ideal edge finish for your glass project.

MIGO Glass can provide further guidance on selecting the most appropriate edge finish for your project.

2. What Are Types of Glass Edge Finishes Classified By Processing Method?

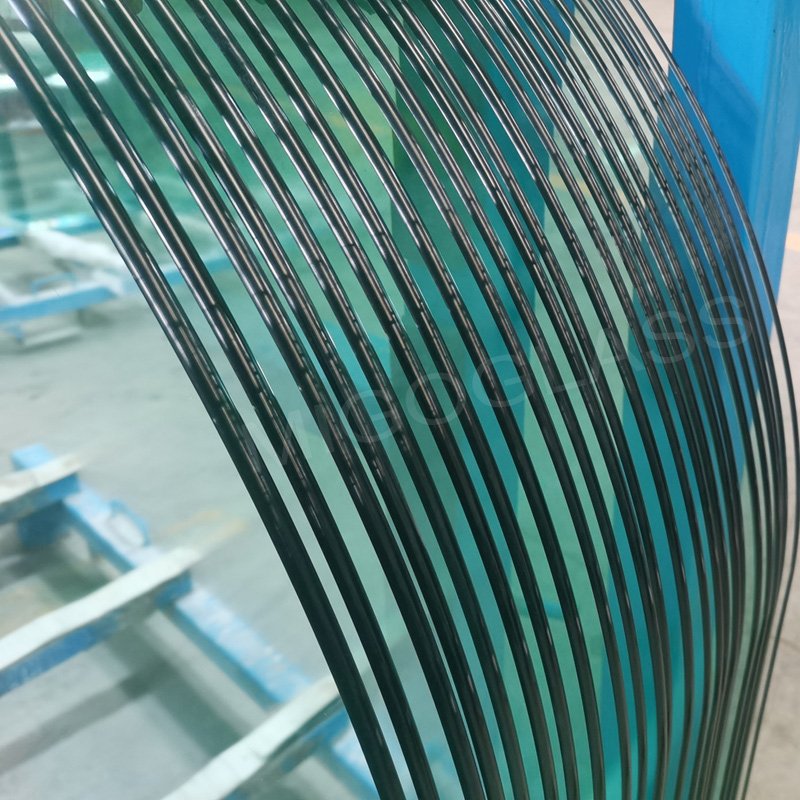

Classified according to the fineness of the edge, glass edge processing can be divided into cutting edge, seamed edge, rough grinding edge, fine grinding edge, and shiny polished edge.

2.1 Cutting Glass Edge

Cutting edge is available when raw glass sheets are produced directly from production lines.

By cutting, the integral glass sheet is divided into various sizes. Otherwise, the glass length will be limitless.

Glass sheets produced at raw glass factories are with Jumbo sizes like 4800×3660mm, 3660×2440mm, etc. Those glass sheets will be second-cut into various sizes and shapes at glass processing factories.

2.2 Seamed Glass Edge

Seamed edge, aka swiped edges, is the second simple glass edgework by just lightly sanding off the sharp edges of the glass side with a sanding belt. This style of edging does not provide a smooth, cosmetically finished edge and is not used for decorative purposes. While it doesn’t add any decorative appeal, a seamed edge significantly reduces the risk of injury from handling or accidental contact with the glass.

Seamed edges are commonly used in glass panels, mirrors, and other glass products to make them safe to handle and prevent any potential injuries from sharp edges.

Also, the seamed edge is the most basic edge requirement for tempered glass.

The seamed edge will not be exposed and is often covered by frames.

3.3 Ground Glass Edge

A ground glass edge refers to a type of glass edge that has been smoothed and finished by grinding down the sharp edges of the glass. This process involves using a grinding wheel or belt to remove any rough or sharp edges, creating a smooth and polished finish.

There are two ground glass edges: rough ground edge and fine ground edge.

A rough ground glass edge refers to a glass edge that has been ground down to remove sharp edges but has not undergone further polishing or finishing to achieve a smooth and polished appearance. This type of edge is typically created using coarse abrasives or grinding tools, which leave a slightly rough texture on the glass edge.

A fine ground glass edge refers to a smooth and polished edge that has been created by grinding down the rough edges of a piece of glass. This process results in a clean and precise edge that is safe to touch and handle. Fine ground glass edges are commonly used in glassware, mirrors, and other glass products to create a finished and professional look.

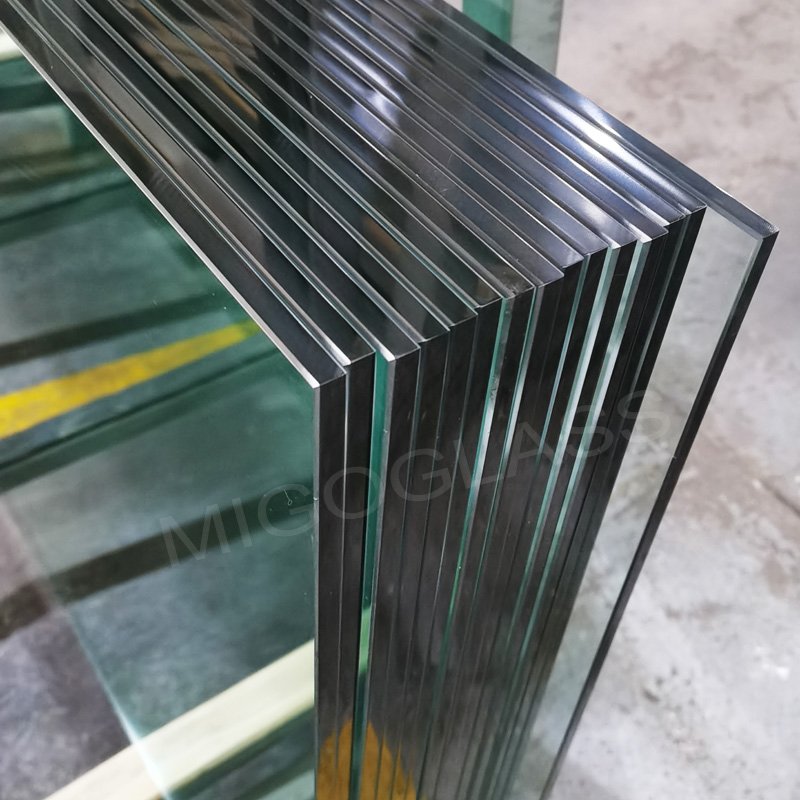

2.4 Shiny polished edge

A shiny polished glass edge refers to a smooth and glossy finish that has been achieved by polishing the edge of a piece of glass. This process involves using abrasive materials and techniques to remove any imperfections and create a sleek and reflective surface. Shiny polished glass edges are often used in high-end glass products, such as decorative items, furniture, and architectural features, to enhance the overall appearance and quality of the glass.

3. What Are Types of Glass Edge Finishes Classified By Edge Shape?

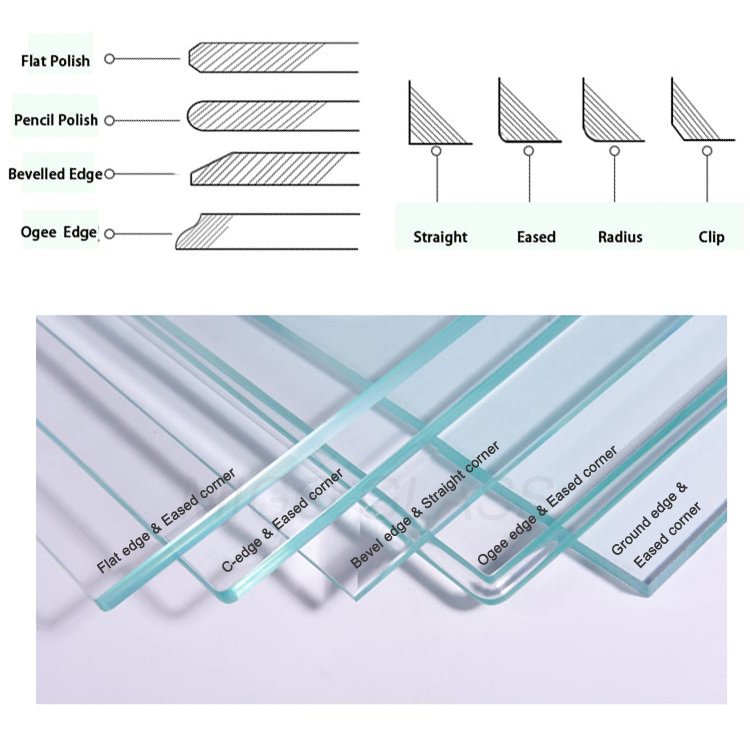

Classified according to edge appearance, common glass edges include flat edge, pencil edge/C-edge/round edge, beveled edge, ogee edge, etc.

3.1 Flat Glass Edge

Flat glass edge refers to the smooth, flat surface of a piece of glass that has been cut and finished to have straight, even edges. Flat glass edges can be achieved through various cutting and finishing processes, such as grinding, polishing, and beveling.

The shower glass door are carefully crafted with a flat polished edge for safety. Careful attention to detail ensures edges are not sharp, reducing the risk of accidental cuts or injuries. The polished edge design enhances the overall aesthetics of the shower room. This edge treatment is a great expression of quality and craftsmanship in bathroom glass.

Additionally, the polished edge is easy to maintain as it minimizes the accumulation of dirt and soap residue, making for easy cleaning and maintenance. This feature helps extend the life of your shower glass door.

Overall, the flat polished edges of shower glass doors embody a blend of safety, style and durability, making them an important element of contemporary bathroom design.

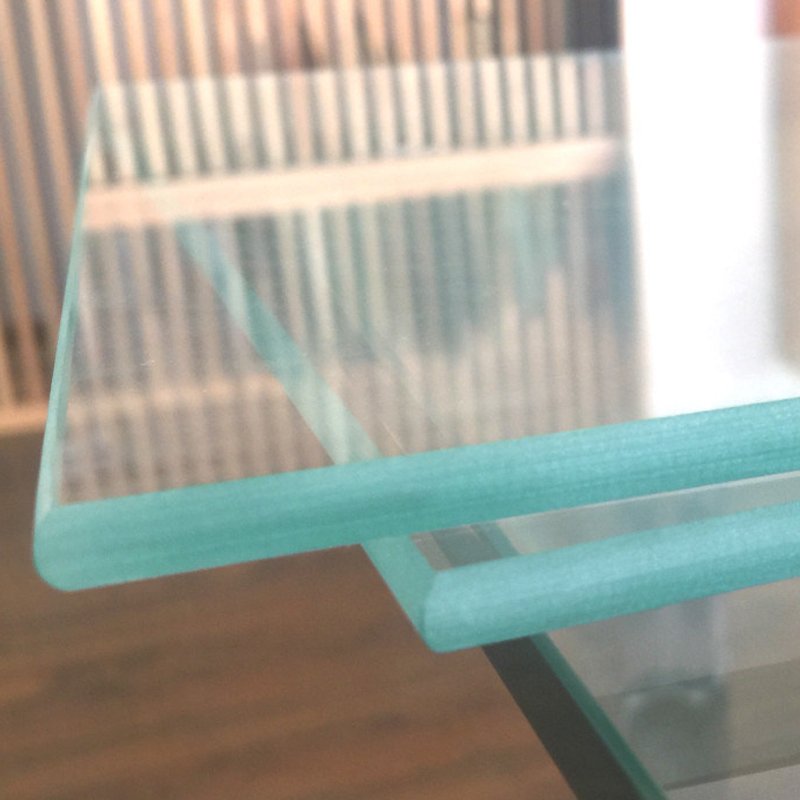

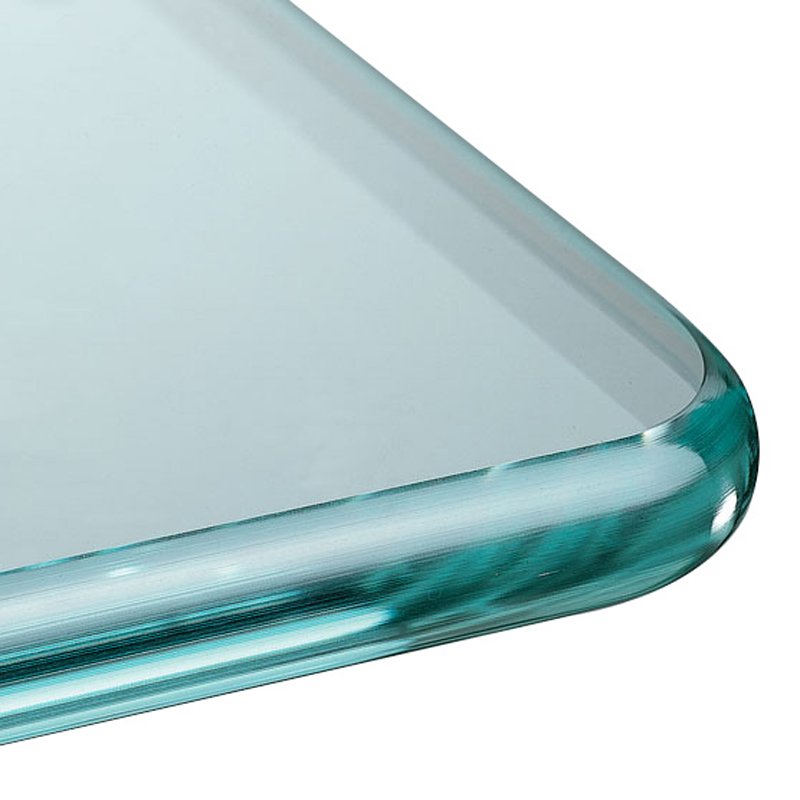

3.2 Pencil Glass Edge

A pencil glass edge, also known as C-edge and round edge, is a type of edge finish for glass that is characterized by a rounded, smooth edge that resembles the shape of a pencil. The rounded edge helps to prevent chipping and provides a more sleek finished look to the glass. Pencil glass edges can be achieved through grinding and polishing processes that shape the edges of the glass into a gentle curve.

This type of edge is commonly used for glass tabletops, shelves, and other applications where a softer, more decorative edge is desired.

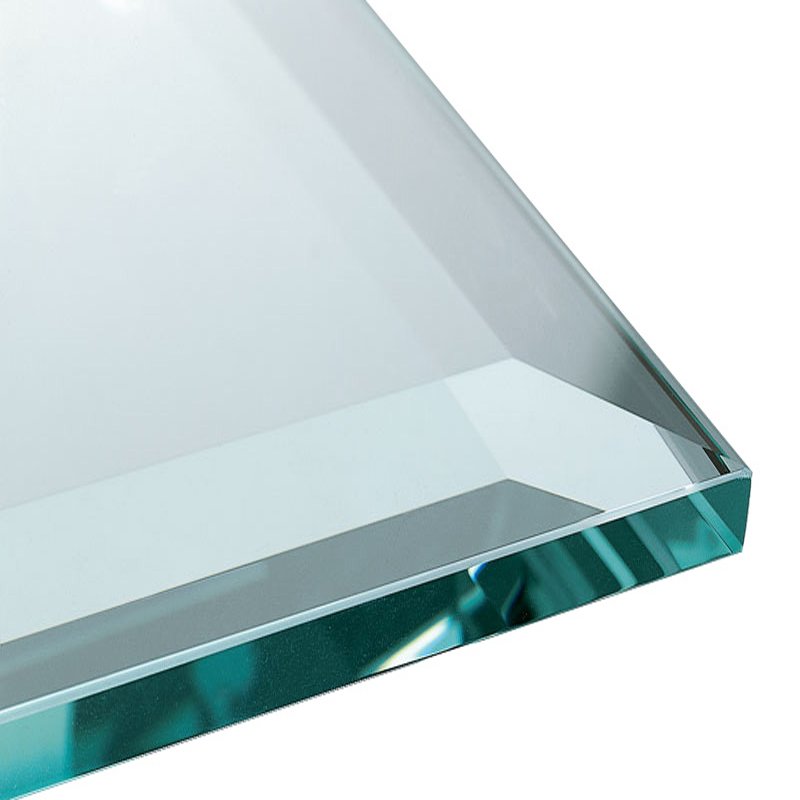

3.3 Beveled Glass Edge

A beveled glass edge is a type of edge finish for glass that is characterized by a slanted or angled edge that creates a decorative and elegant look. Beveled edges are achieved by grinding and polishing the glass at a specific angle, typically around 45 degrees, to create a chamfered edge that reflects light and adds dimension to the glass. Beveled edges are commonly used for mirrors, glass tabletops, doors, and other decorative glass applications. The angled edge of beveled glass adds a touch of sophistication and can enhance the overall aesthetic of the glass piece.

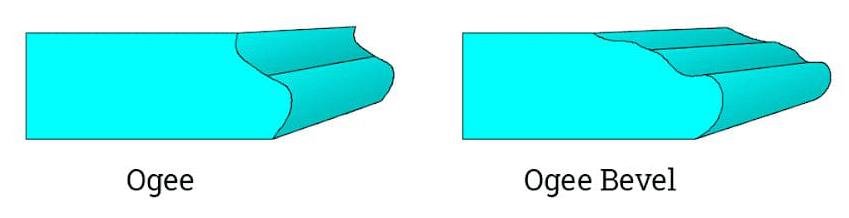

3.4 Ogee Glass Edge

An ogee glass edge is a type of edge finish for glass that features a distinctive S-shaped curve. This edge profile is created by grinding and polishing the glass in a way that creates a concave arc followed by a convex arc, resulting in a graceful and decorative edge. The intricate curves of the ogee edge can catch and reflect light, enhancing the overall aesthetic of the glass and creating a visually appealing finish.

The ogee edge is often used for glass tabletops, shelves, and other decorative glass applications where a more ornate and elegant look is desired.

4. Conclusion

When choosing a glass edge type, several factors come into play, such as aesthetic preferences, functionality, safety requirements, and budget constraints. Whether you prioritize a sleek and modern finish or prioritize safety and durability, there’s a glass edge treatment to meet your needs. Understanding the characteristics and applications of different edge types allows you to make informed decisions when selecting glass for your project, ensuring a perfect balance between style and functionality.

Different types of glass edge finishes serve different specific purposes, and it’s crucial to consider the intended application and design requirements. Proper handling and installation of the glass with the appropriate edge type are essential for its long-term structural performance and safety. By selecting the right edge finish and following the correct installation procedures, you can optimize the functionality, visual appeal, and overall safety of the glass system. Careful consideration and informed choices will help you achieve the desired results in terms of both aesthetics and functionality for your project.