A reliable shower glass factory consistently produces high-quality, industry-standard shower enclosures and glass panels. They are known for customer satisfaction, attention to detail, and using premium materials and processes.

If you want to get high-quality tempered glass products, it is crucial to choose a reliable shower glass factory. MIGO Glass is a professional shower glass manufacturer with over 20 years of experience in the industry. Here is the ultimate guide to help you select a reliable shower glass factory.

1. What Is Reliable Shower Glass Factory?

A reliable shower glass factory is a manufacturer that consistently produces high-quality shower glass panels for doors or enclosures that meet or exceed industry standards. This type of glass shower factory is known for their commitment to customer satisfaction, attention to detail, and use of high-quality materials and manufacturing processes.

Key characteristics of a reliable shower glass factory include a strong reputation, robust quality control measures, and the use of top-grade materials. They will have modern equipment, skilled workers, and certifications like ISO9001 and ISO14001, indicating adherence to international quality management standards.

Reliable factories prioritize customer service, offering responsive support and comprehensive warranties on their products. Look for certifications from reputable authorities like SGS, CSI, and CE, which demonstrate that the factory’s products meet critical safety, performance, and environmental requirements.

While price is a consideration, it’s crucial not to compromise quality for a lower cost. A reliable shower glass factory will provide a fair, competitive price without sacrificing the integrity of its manufacturing processes and end products.

2. What Key Considerations When Choosing Reliable Shower Glass Factory?

2.1 Clean and tidy production workshop and advanced production equipment

Evaluate the factory’s production capabilities, including the types of glass they can handle, their cutting and tempering equipment, and their quality control processes. A well-equipped factory is more likely to produce durable and reliable shower glass.

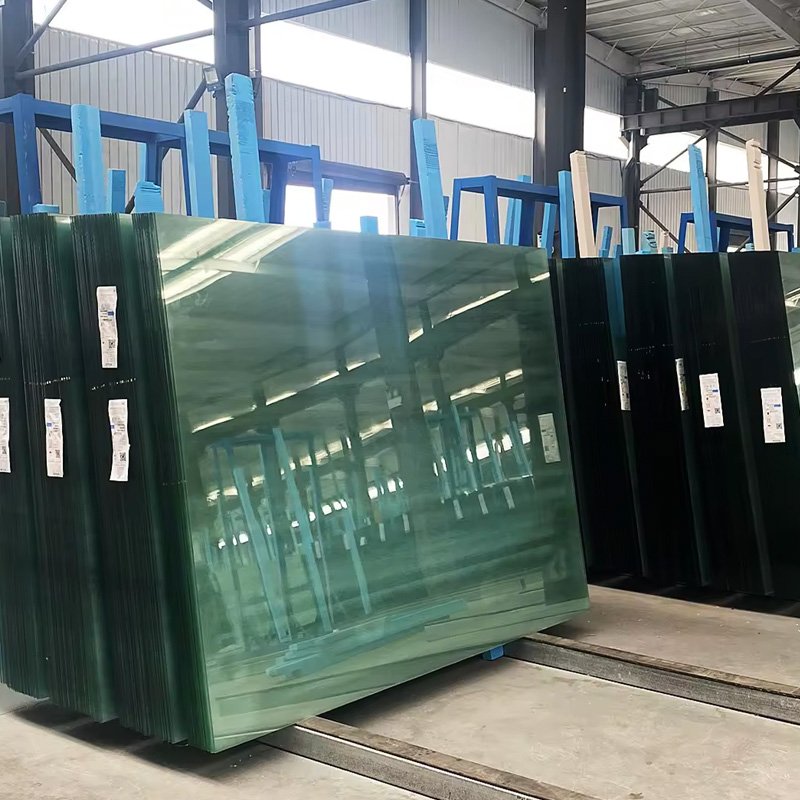

Checking whether the glass factory site is clean, well-lit, and well-ventilated and whether the glass is stored in an orderly manner are all standards for testing a factory’s management capabilities.

Advanced production equipment is a necessary condition for the production of different shower glass products. Migo Glass factory covers an area of 18,000sqm and has 90 workers, Our annual production capacity for tempered glass reaches an impressive 3 million square meters.

Many of our factory’s equipment are imported, such as the Italian Intermark cutting machine and the Dutch GLASTON tempering furnace. The maximum size that the cutting machine can handle is 3300*6000mm, and the maximum tempering size of the tempering furnace is 2440*6000mm. Our edge grinding machines and chamfering machines can also meet the edge processing of various bathroom glasses. The most noteworthy is our newly invested glass self-cleaning production line and explosion-proof film coating line, which can adapt to the self-cleaning of bathroom glass and safer packaging processing.

The factory’s advanced equipment allows us to produce a variety of customized shower glass products. And also can make sure to make high-quality products and stable supply to customers. Migo Glass can consistently meet deadlines and provide timely updates on production.

2.2 High quality raw material glass (annealed glass)

Float glass raw material is one of the basic foundations for manufacturing high-quality and durable tempered glass.

MIGO Glass has its own annealed glass production plant. The production date of float glass must be within 3 months. The freshness of the glass must be guaranteed because glass is prone to mold if stored for a long time.

Migo Glass also work with big annealed glass brands like Jinjing and CSG, their annealed glass can be pointed as your raw material glass for producing the glass shower door.

2.3 High-standard QC inspection

The complete QC system ensures the quality of raw materials and the perfection of each process in the glass production process.

MIGO Glass has a high standard glass inspection during the production and after production.

Our inspection items include but are not limited to: the thickness of the raw material glass, surface flaws, bubbles, scratches, cutting size error controlled within 0.2mm, the position and size of the slots strictly in accordance with the drawings, the curvature of the glass surface after tempering, size measurement, etc., to ensure that the bathroom glass we produce appears in front of customers in perfect shape.

2.4 Certifications and Compliance

Ensure the factory is compliant with industry standards and has the necessary certifications, such as ISO, SGCC, or ANSI. This demonstrates their commitment to quality and safety.

MIGO Glass takes pride in delivering high-quality shower glass products that meet the standards of over 30 countries and regions. Our tempered shower glass complies with EN12150 and EN12600 standards, and we possess CE (European market)and SGCC certificates(USA market) to validate our commitment to quality further.

2.5 Look for Experience and Reputation

Choose a factory that has been in the business for several years and has a proven track record of delivering high-quality products. Check their website, reviews, and industry references to gauge their reputation.

2.6 Understand the team and company culture

Good team cohesion promotes employee collaboration and enhances corporate cohesion. A healthy and positive corporate culture attracts talents, enhances employee identity, and improves work efficiency. A strong team and culture ensure the smooth implementation of strategies and enhance innovation and competitiveness. In a rapidly changing environment, a united and collaborative team and a culture that adapts to changes can help companies quickly respond to challenges and seize opportunities.

Corporate leaders should attach great importance to team building and corporate culture cultivation, and regard them as the key support for the sustainable development of the company. Only by building an excellent team and culture can a company achieve long-term prosperity.

Experienced production team and QC department, most of them have more than 15 years’ experience in the glass production field, which ensure smooth production

High-quality sales team ensures barrier-free communication with customers and timely provision of bathroom glass solutions to customers

Logistics and transportation department ensures that our own raw glass production base can provide a stable supply of raw glass to the bathroom glass deep processing production base, and also ensures smooth export.

Migo Glass is committed to providing customers with one-stop bathroom glass solutions.

3. Frequently Asked Questions When Selecting Reliable Shower Glass Factory.

You can also deepen your understanding of the glass processing factory by asking the following questions:

- Who Are Their Current Customers?

This can reflect the quality level of the factory’s glass and verify whether it meets your market positioning.

The company’s market positioning should be based on the quality of its glass products, that is, the characteristics and advantages of the products. In other words, it represents the success of its tempered glass and ordinary glass products.

Show photos and videos of bathroom glass produced in the past, from which you can find glass products that meet your market needs.

But the most intuitive way to understand a factory is to visit the factory. Migo Glass warmly welcomes every customer who is interested in cooperation to visit our production workshop and sample room, learn about our company and team, and become your most trusted shower glass supplier.

- What materials do you use for the glass?

You want to ensure the factory uses high-quality, durable materials such as tempered glass for safety and strength.

- Can you customize the glass to specific dimensions and designs?

Customization is crucial for fitting various shower sizes and styles.

- What is your production capacity?

Understand if the factory can meet your volume requirements, whether small or large scale.

- What are your lead times?

This will help you plan your inventory and deliveries effectively.

How do you ensure the quality of your products?

Ask about their quality control processes and if they conduct any third-party testing.

- What is the cost involved?

Inquire about pricing and whether it includes any additional fees for customization or shipping.

- Do you offer samples for quality inspection?

Requesting samples can help you assess the quality firsthand.

- What is your warranty policy?

A warranty can provide peace of mind regarding the durability and quality of the glass.

- What is your customer service like after the sale?

Post-sale support is crucial for addressing any issues that may arise.

- How do you handle any defects or damages that occur during shipping or installation?

It’s important to know their process for addressing product issues post-delivery.

- What is the process for placing an order and what are the payment terms?

Clarify the steps involved in ordering and their accepted payment methods.

By addressing these FAQs, you can make a more informed decision when choosing a shower glass factory that meets your specific needs and expectations.

4. Final Thoughts

Selecting a certified, reliable shower glass manufacturer is crucial for ensuring the durability, safety, and long-term performance of your shower system. MIGO Shower Glass, a professional manufacturer with over 20 years of industry experience, uses premium materials, provides customized solutions to meet your specifications, and offers comprehensive warranties – demonstrating their commitment to delivering superior products and customer service you can trust. By partnering with MIGO Shower Glass, you can have peace of mind in the quality and reliability of your shower enclosure or door.

Any questions, please let us know.