When it comes to decorative glass, two common options are clear float glass and low iron float glass. These options meet the different needs and preferences of customers who want specific features in their glass products. MIGO Glass is the leader in the Chinese glass industry, offering a wide range of glass solutions tailored to different requirements.

In this blog, let’s dive into a comprehensive examination of the differences between clear float glass and low iron float glass to gain a deeper understanding of their unique properties and decorative uses.

1. What Is A Clear Class?

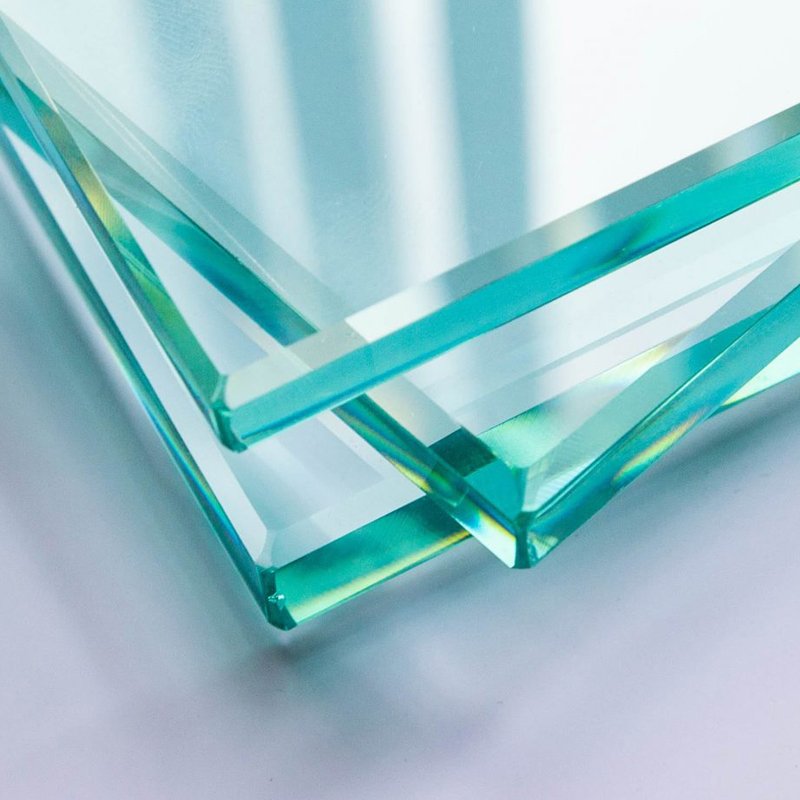

Clear glass, also known as ordinary glass, is primarily composed of a blend of silica (sand), sodium carbonate, and limestone. The manufacturing process involves melting these raw materials together at high temperatures. However, the presence of iron oxide impurities in the silica and other components gives clear glass a slight greenish tint.

Despite the greenish hue, clear glass remains transparent, allowing light to pass through without significant distortion. It is widely used in various applications, including windows, glassware, mirrors, and architectural features. The greenish tint is often more noticeable in thicker or larger pieces of glass.

To reduce the green tint and achieve a purer, colorless appearance, manufacturers can employ additional processes such as refining and decolorizing agents. These methods help produce ultra-clear glasses commonly used in high-end applications like display panels, optical lenses, and specialty glass products where maximum clarity is required.

While clear glass may have a subtle greenish tint, its transparency and versatility make it a popular and widely-used material across different industries and everyday objects.

2. What Is A Low Iron Glass?

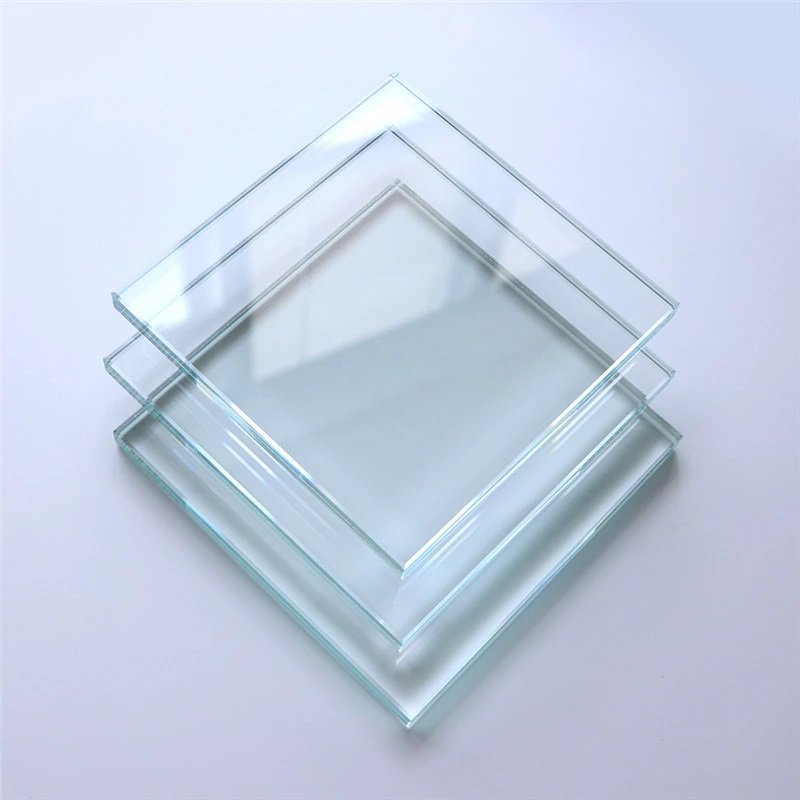

Low iron glass, also known as extra-clear glass or ultra-clear glass, is a type of glass that contains a reduced amount of iron compared to standard clear glass. While clear glass has a slight greenish tint due to iron oxide impurities, low iron glass undergoes a refining process to remove a significant portion of these impurities.

By reducing the iron content, low iron glass achieves exceptional transparency and clarity. It minimizes the inherent greenish tint present in clear glass, resulting in a glass that appears almost colorless. This high level of transparency allows for true color representation and excellent light transmission.

Low iron glass is highly sought after in applications where maximum clarity is desired, such as architectural projects, high-end display cases, solar panels, aquariums, and specialty glass installations. Its superior visual properties make it ideal for showcasing objects, enhancing natural lighting, and creating a sense of openness.

While low iron glass offers remarkable clarity, it is typically more expensive than standard clear glass due to its manufacturing process. However, for applications that require exceptional transparency and minimal color distortion, low iron glass is the preferred choice.

3. What Is The Difference Between Clear Glass vs Low Iron Glass?

The difference between clear and low-iron glass lies in the increased transparency of the latter. This makes the low-iron glass more suitable for applications like frameless glass walls, back-painting, UV-bonded display cases, partitions, dividers, and other similar uses.

3.1 Different Color

Although clear glass does not have a high iron content, it does have a higher iron content than low-iron glass. These higher contents create a green tint that becomes more prominent as the glass becomes thicker.

Low-iron glass is a type of glass that contains less iron oxide. It is also known as low iron glass and extra-clear glass.

Low-iron glass contains trace amounts of iron and is colorless. Unlike clear glass, low-iron glass remains clear when viewed from the side regardless of thickness. There is a slight bluish tint when looking at the edge of a piece of glass, but this is masked by the surrounding colors. In clear glass sheets, as the thickness of the glass increases, the green tint becomes more obvious.

3.2 Different Transparent

The main difference between clear glass and low iron glass is the light transmittance. The reflectivity of low iron glass is lower than that of clear glass, which can reduce the optical reflection on the glass surface and has higher gloss, thus making the light transmittance higher and more decorative and practical. In comparison to clear glass, due to the color difference, light will be reflected, making it look lighter.low iron glass is made of special raw materials and process technology on the basis of clear float glass. Compared with clear glass, low iron glass has a higher light transmittance, and can even reach a transmittance of more than 90%. The entire glass image will be clearer and more transparent, and it has the characteristics of high transparency. Compared with low iron glass, clear glass has a relatively lower light transmittance.

3.3 Different Self-Explosion Rate

The self-explosion is a phenomenon of fragmentation that occurs without external force. Glass fragments spread radially around the origin of the explosion. Two larger fragments will appear at the starting point of the self-explosion, showing the characteristics of “butterfly spots”. During the production process of low-iron glass, high-purity raw materials are used to remove impurities and bubbles. Through advanced refining processes, the purity and uniformity of low-iron glass are improved. Low-iron glass is stronger and more durable than ordinary glass due to its special physical properties. Low-iron glass has higher strength and toughness than ordinary glass and is less likely to break even if it is hit by a huge external force. At the same time, the thermal expansion coefficient of low-iron glass is much smaller than that of ordinary tempered glass, and it is less affected by thermal expansion or contraction, thereby reducing the risk of self-explosion.

3.4 Different UV Transmittance

The ultraviolet transmittance of low iron glass is only 0.5%, while the ultraviolet transmittance of white glass is higher, generally above 5%. It can be seen that low iron glass performs better in resisting ultraviolet rays. Low-iron glass can also allow more natural light to enter and block ultraviolet rays (UV). It has better anti-ultraviolet properties, which can effectively avoid ultraviolet damage to objects, allowing you to enjoy beautiful scenery during the day while protecting your home. thing.

3.5 Different Price

The price of low iron glass is usually higher than that of clear glass because its production control is more difficult, its technical content is higher, and its manufacturing costs are higher. Therefore, the price of low iron glass is relatively high.

1) Material cost: The raw materials used in low iron glass are of high quality and purity, and the production cost is relatively high.

2) Production process: The production technology of low iron glass is relatively high, requiring more stringent production processes and technologies, and the cost is higher. During the production of clear glass, the removal of impurities, especially iron oxide, requires additional steps and specialized equipment. Therefore, the price of low-iron glass is 10%-30% higher than that of clear glass

3.6 Different Application

The added value of low iron glass is higher than that of clear glass, so low iron glass is more used in high-end architectural projects, display cases, museum exhibits, solar panels, aquariums, and any other application where maximum light transmission and minimal color distortion is desired., while clear glass, is commonly used in various applications where color distortion is not a significant concern. It is often used in windows, glass containers, general glazing, and architectural applications.

4. How To Choose Between Clear Glass vs Low Iron Glass?

Clear glass and low iron glass differ primarily in terms of transparency and color tint. While both types of glass can be used in various applications, low iron glass offers enhanced clarity and greater light transmission.

When considering visual preference, clear glass may be suitable if the slight greenish tint is acceptable or complements the overall design. On the other hand, low iron glass is the preferred choice when maximum transparency and minimal color distortion are desired.

For specific application requirements, low iron glass is recommended for projects that require true color representation and excellent light transmission. This makes it ideal for architectural features, display cases, solar panels, and other similar applications. Clear glass, with its slight greenish tint, may be more suitable for general applications where the tint is acceptable.

Budget considerations should also be taken into account, as low iron glass tends to be more expensive due to its refined manufacturing process and superior clarity. If cost is a significant factor, clear glass may be a more economical choice.

The scale of the project and the size/thickness of the required glass should also be considered. Clear glass’s greenish tint becomes more noticeable in thicker or larger pieces. If thicker glass or large glass panels are anticipated, low iron glass can minimize the tint and provide better clarity.

To purchase custom or OEMD/ODM clear glass or low iron glass in bulk, you can visit the MIGO Glass website. They offer premium custom-cut glass solutions at affordable prices.

You can make an informed decision between clear glass vs low iron glass that aligns with your specific needs and priorities by considering factors such as visual preference, application requirements, budget, and project scale.

5. Conclusion

The choice between clear glass and low-iron glass depends on the specific requirements and budget of your project. If you prioritize maximum clarity and minimal color distortion, low-iron glass will be your first choice. However, if cost is a factor and a slight green tint is acceptable, clear glass may be the more cost-effective option.

If you have any further inquiries or specific glass needs, you can contact MIGO Glass directly and their experts will help you choose the type of glass that best suits your requirements and budget.