Shower Glass Tempering

Shower glass tempering, shower glass toughening and shower glass strengthening all refer to the same process. It is the fabrication process to heat the glass closely to the softening temperature and then cool it evenly and quickly. It causes compressive stress on the surface of the glass and tensile stress on the interior.

MIGO Glass manufactures and wholesales tempered shower glass at competitive factory price.

Table of Contents

1. What is Tempered Glass

Tempered shower glass is a type of glass that has been processed to increase its safety, strength, thermally stablity and resistance to breakage.

Shower glass tempering process improves the mechanical strength, thermal stability and safety of glass panels. Tempered glass is several times stronger than ordinary glass. It can effectively resist breakage and greatly reduce the risk of injury of accidental breakage. Tempered glass has many advantages as followed.

1.1 High Mechanical Strength

The 6 mm thick tempered glass can withstand the impact of a 227-gram steel ball at a height of 2.5 meters from the glass.

1.2 Rapid Temperature Changes.

It can withstand rapid temperature changes from 40°C to 300℃, and the glass will not break.

1.3 Strong Safety Performance

When it is broken by excessive external force, the fragments will be granular and difficult to hurt people.

2. Shower Glass Tempering Processes

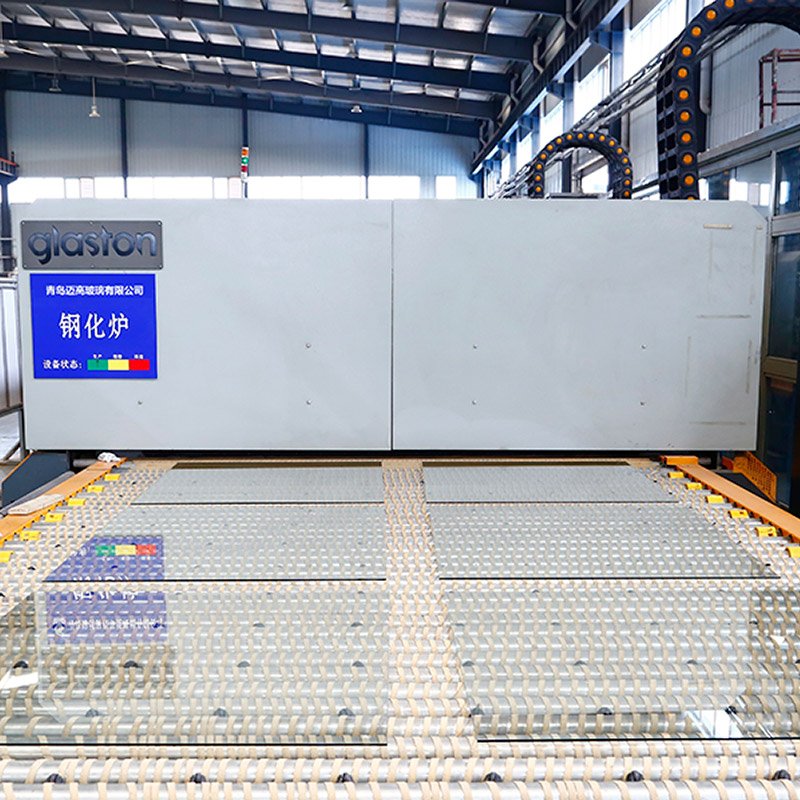

MIGO Glass is one of the largest tempered glass manufacturers and suppliers. We have the latest shower glass tempering machines used in the tempered glass manufacturing process. Tempered glass machines have temperature control systems and high-pressure air jets. It takes heating, quenching, and cooling processes to let the production effectively and efficiently.

The shower glass tempering processes include the following steps.

2.1 Preparation

The shower glass tempering process begins with the shower glass being cut to size and shape. You should clean the glass and thoroughly remove any dirt, dust, or contaminants that could affect the tempering process.

2.2 Heating

The shower glass tempering machine consists of a heating chamber or furnace. It automatically accomplishes the high-temperature heating process. The exact temperature and heating time depend on the thickness and type of glass processed.

Generally, 5-6mm shower glass takes a heating temperature of 700°C for about 240 seconds, then cooling down for about 150 seconds. 8-10mm glass takes a heating temperature of 700°C for about 500 seconds, then cooling down for about 300 seconds.

2.3 Quenching

After the shower glass reaches the desired temperature, it is rapidly cooling down by the quenching process. Quenching involves directing high-pressure air or jets of cold air to the glass surface. This rapid cooling process creates a state of high surface compression and internal tension within the glass. The shower glass get enhanced strength and safety properties.

2.4 Cooling

Once the quenching process is complete, the glass undergoes controlled cooling to stabilize its internal structure. This gradual cooling phase reduces the residual stress within the glass and helps to prevent spontaneous breakage.

2.5 Inspection

Take the Visual inspections, measurements, glass strength and surface compression, and overall quality, etc.