Shower Glass Screen Printing

Shower glass screen printing is the fabrication process to create a special kind of decorative glass with text and patterns.

Screen printing on glass can enhance the appearance and value of shower glass. It can make this ubiquitous, practical, and durable material into a versatile glass picture. It also has durable and scratch-proof, with an anti-glare effect and safety-glass properties. Screen printed glass typically has acidic and moisture-resistant features that can preserve the colors for decades.

Table of Contents

1. Characteristics of Glass Screen Printing

Multiple types of inks include oil-based, water-based, synthetic resin, emulsion powder and other types of inks.

The layout is soft. The screen printing layout is soft and has a certain degree of elasticity, suitable for printing on glass products.

The ink layer is thick and has strong coverage.

It is suitable for the surface shape and area of glass products. It also has great flexibility and applicability for printing the size of curved and spherical glass products.

2. How to Print on Glass?

Follow 8 steps to create precise and durable images on the shower glass surface.

2.1 Design Creation. Create a design on a template or stencil.

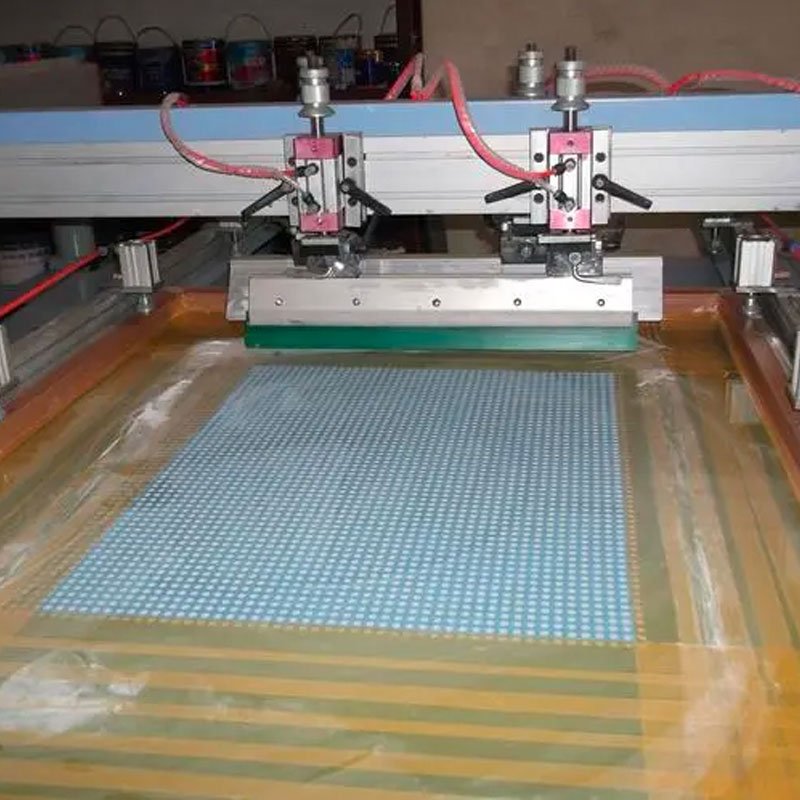

2.2 Ink Application. Use a squeegee to spread glass glaze (glass ink, glass printing material) across a mesh screen. The design blocks ink from flooding certain areas while allowing ink to pass through in the desired design areas.

2.3 Ink Transfer. Exerting pressure with a scraper to transfer it onto the surface of the glass product. Force the ink through the mesh screen onto the glass surface, resulting in a high-quality image. The printing process allows for precise detailing, and the degree of transparency can be adjusted.

2.4 Pattern and Solid Areas. This method of screen printing on glass is ideal for creating repeatable patterns and solid areas on glass panels. These patterns can serve to separate or conceal specific areas.

2.5 Color Limitations. When using screen printing on glass, the colors are limited to a maximum combination of four colors. Each color requires its own screen and setup process.

2.6 Tempering and Firing. The glass undergoes tempering or heat strengthening, while the ink is “fired” onto the glass at a high temperature. The text or patterns emerge after the glaze is baked and dried. This process fuses the ink to the glass surface.

2.7 Image Durability: Heavier ink coverage enhances the durability of the printed image. Coatings can be applied to increase resistance and enable exterior applications.

2.8 Ink Types. The inks used in glass screen printing can be organic or inorganic, depending on the specific application requirements.

3 Screen Printing on Glass Applications

3. 1 High Volume Production

Shower glass screen printing is suitable for batch production with automatic machines with the same repeated design.

3.2 Surface Finishes

The availability of opaque and translucent colors in screen printing enables a wide range of surface finishes, adding versatility to the printed.

3.3 Flat Shower Glass

Its ability to handle large batch of shower glass screen printing. It ensures efficient production and consistent quality.