Shower Glass Edging

Shower glass edging is the glass deep fabrication process to refine and shape the edges and corners of the cut glass. Edging glass is essential for shower glass to make sharpe edges smooth, eliminate chips, improve functional tolerance functionality and get an aesthetic effect. MIGO Glass offers cutom shower glass edging services with various glass edge types.

Table of Contents

1. Top 3 Shower Glass Edge Types

The most popular glass edge types for various applications mainly include flat polished edge, pencil polished edge, beveled edge, seamed edge, mitered edge and ogee edge. Considering aspects such as aesthetics, functionality and cost, flat polished edge, pencil polished edge, beveled edge are the common shower glass edge types. Which glass edge finish is best for you depending on personal preference and shower room design needs.

1.1 Flat Polished Edge

The most common and universally accepted edge glass edge type in shower glass industry is flat polished edge. The flat polished treatment grinds and polishes the edges of the glass, making it smooth and slightly beveled flat surface.

Flat polished edge not only enhances the smooth and stylish appearance of the glass, it also eliminates sharp edges, reducing the risk of injury. Flat polishing treatment is simple, affordable and functional. It is suitable for various types of glass, including tempered glass and ordinary shower glass.

1.2 Pencil Polished Edge

The pencil polished edge type get its name from the smooth and round design that looks very much like a pencil. This type glass edge is rounded to a half-circle or ‘c’ shape. It provides a softer and more smooth appearance that makes it great for mirrors, dividers and bathroom decorations.

1.3 Beveled Glass Edge

Beveled edge are created by cutting and shaping the edges of the shower glass at a specific angle, typically 45 degrees. Beveled edges add elegance and suitable for mirrors, frameless shower door and other decorative glass pieces in bathroom.

2. Shower Glass Edge Edging Processes

The glass edge does not look nice after shower glass cut to size. Sharp edges will lead to injuries. So the shower glass edging process is essencial before the final glass tempering process. The edging glass process includes glass edge grinding and glass edge polishing sub processes.

2.1 Glass Edge Grinding Process

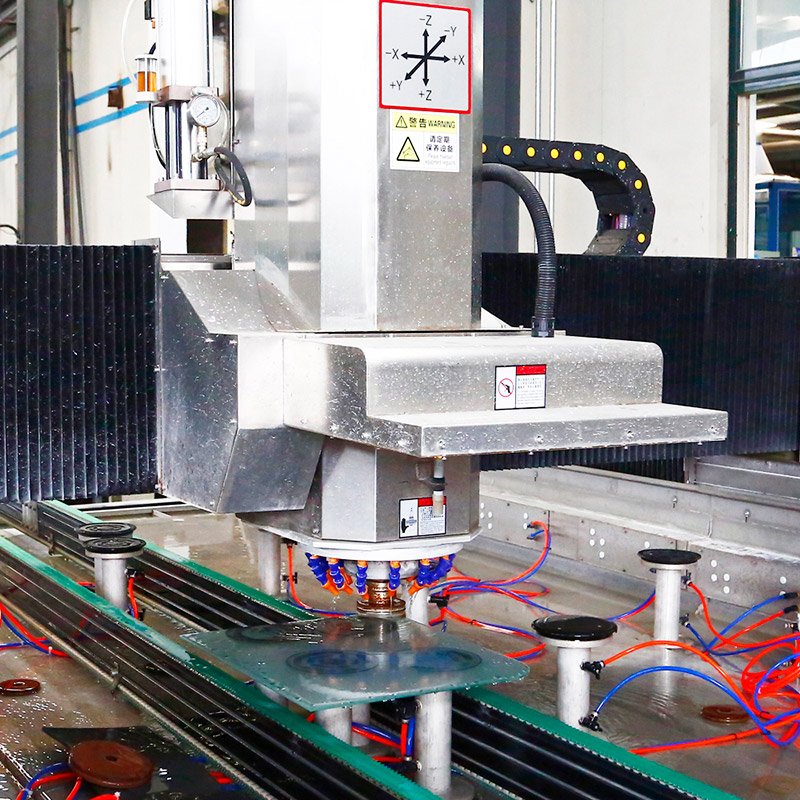

Grinding glass edges is the first step to process the perfect glass edges. How to grind glass edges? Our experienced technicians use CNC glass edge grinding machine to grind the edge in our custom glass work factory. MIGO Glass has latest CNC glass edge grinder, 4-edge glass grinder, and portable glass edge grinding machine for glass edging tasks.

Preparation. Choose appropriate grinding wheels and abrasive tools according to the accuracy, glass type, glass thickness and grinding pattern. Spindle speed, feeding speed will affect the grinding quality. Finally, select cooling and flushing agents to ensure normal processing.

Grind the Edge. The glass edge grinding machine moves the grinding head or the glass work-piece according to the designated paths and contours. The abrasive grinding wheel removes a mount of materials from the sharp edges. The surface of the glass edge will be slightly rough and has a greenish tint.

Optional Processes. Perform additional processes such as edge polishing, drilling, or engraving if you have specific requirements.

2.2 Shower Glass Polishing Process

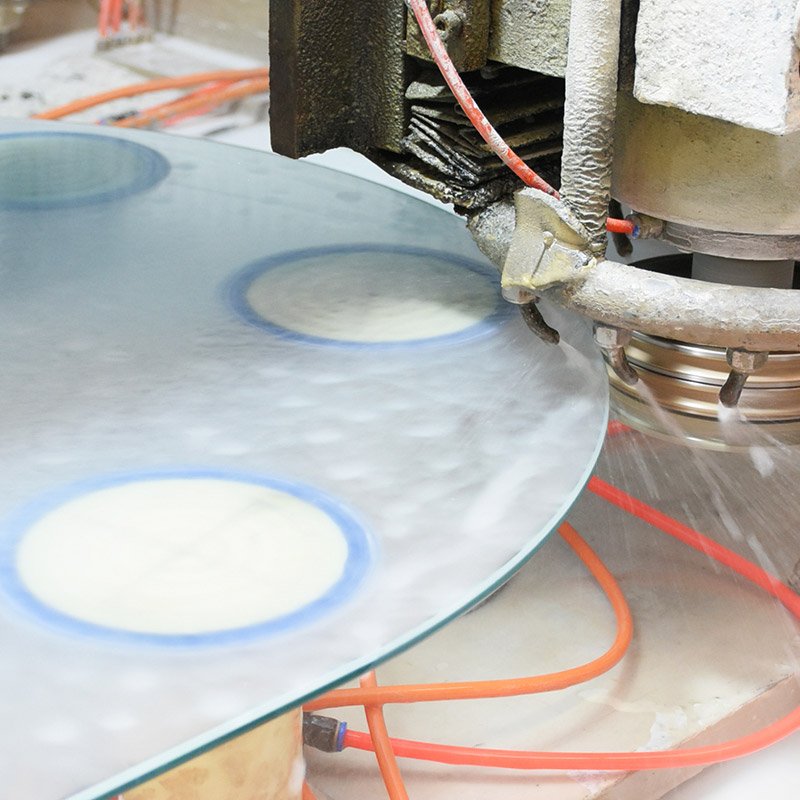

The shower glass edge polishing process removes any scratches, obtains a transparent glossy glass edge which gives the glass additional attractiveness. It is another important process. Polished edge glass panels applications cover shower doors, shower enclosures and windows, mirrors, etc.

How to polish glass edges? Polishing glass edges by hand is possible when on site installation. MIGO Glass has the latest CNC glass polishing machines for precise and automated glass edge polishing operations. It combines computer numerical control (CNC) technology with polishing tools and techniques to achieve high-quality and consistent glass polishing results.

CNC glass edge polishing steps. Choose appropriate polishing tools such as polishing pads or abrasive polishing compounds. Glass type, glass thickness, surface condition, and finish accuracy are factors to consider. Securely fix the glass piece onto the moving table and carefully align and calibrate CNC glass polishing machine. Specify the polishing speed, pressure, and other parameters based on the glass type and desired finish. CNC edge polishing machine for glass moves the tools or the glass piece according to the CNC paths and contours. It automatically start the polishing action to the glass surface. Inspect the polished glass surface to ensure the desired level of smoothness, clarity, and appearance.