Shower Glass Acid Etching

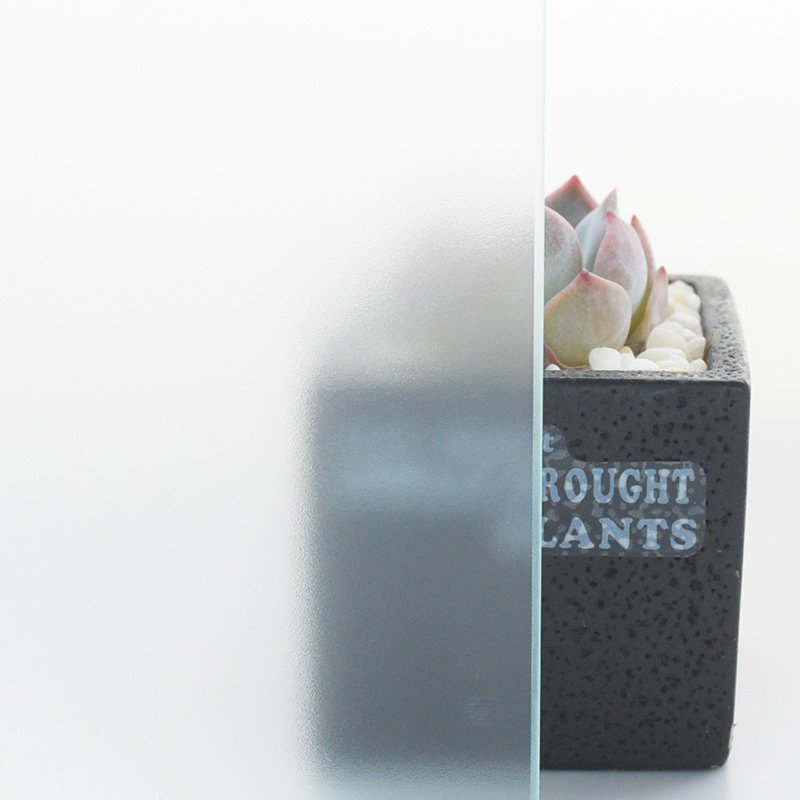

Shower glass acid etching is the shower glass fabrication process to use hydrofluoric acid etching glass process creating a matte surface finish on one or both sides of the shower glass. This unique transformation imparts a semi-permeable quality to the shower glass. It allows light to pass through while maintaining a level of privacy. This technique is ideal for shower doors and shower enclosures, where functionality and aesthetics are of utmost importance. MIGO Glass provides custom acid etching glass for your demands at competitive factory price. at co

Table of Contents

1. How to Etch Glass with Hydrofluoric Acid?

1.1 Hydrofluoric acid

is a highly corrosive substance that reacts with the glass surface during the acid etching process. When hydrofluoric acid comes into contact with the glass, it reacts with the silica molecules on the surface. The acid molecules remove or dissolve the silica, creating a microscopic rough texture on the glass. This texture scatters and diffuses light, giving the glass a matte or frosted appearance.

1.2 Acid Etching Glass Process

The depth and intensity of the etching can be controlled by adjusting factors such as the concentration of the acid, the duration of the etching process, and the application technique. By carefully regulating these variables, artisans can achieve different levels of opacity and texture, resulting in various degrees of translucency and privacy.

It’s important to note that working with hydrofluoric acid requires expertise and caution due to its corrosive nature.

2. Is Acid Eching Glass Surfaces More Durable?

Acid etched glass surfaces can become more durable to some extent. During the acid etching glass process, the shower glass surface will be corroded. It will form fine uneven textures, thereby increasing the friction and slip resistance of the surface. This texture can improve the slip resistance of the glass and reduce the risk of slips caused by wet environments.

Shower glass acid etching can only make minor changes to the glass surface. It can not significantly improve the overall hardness or strength of the glass. The durability of the glass itself depends on its manufacturing process and the quality of its raw materials.

MIGO is the professional shower glass expert. We specializes in shower glass production and deep processing. MIGO has its own shower glass acid etching factory.

The quality glass material, the right thickness, and the right installation method can ensure long-term usage and durability.

3. MIGO Offers Acid Eching Service

Hydrofluoric acid is a highly corrosive substance that reacts with the glass surface during the acid etching process. When hydrofluoric acid comes into contact with the glass, it reacts with the silica molecules on the surface.

The acid molecules remove or dissolve the silica, creating a microscopic rough texture on the glass. This texture scatters and diffuses light, giving the glass a matte or frosted appearance.

The depth and intensity of the etching can be controlled by adjusting factors such as the concentration of the acid, the duration of the etching process, and the application technique. By carefully regulating these variables, artisans can achieve different levels of opacity and texture, resulting in various degrees of translucency and privacy.

It’s important to note that working with hydrofluoric acid requires expertise and caution due to its corrosive nature.